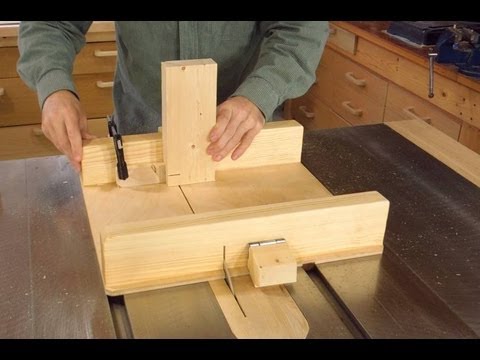

A relatively quick and simple method for cleaning up your tablesaw cuts

An out-of-aligned blade can cause sloppy cuts and kickback. But it is a pretty straightforward fix. You do not need special tools to do this, you could do it with a combination square, but why use what you've got when you can buy a specialized tool, right?

Tamar uses an A-Line-It Kit, which is a dial caliper with an arm that rides in the miter slot of the saw.

Step by step to align a tablesaw blade to the fence:

- Unplug the table saw.

- Raise the table saw blade all the way and then back it off about 1/16 inch

- Insert dial caliper in the miter slot and make sure the fit is snug.

- Index the caliper close to a tooth on the blade (but not on a tooth). Mark this spot with a Sharpie.

- Rotate the face of the indicator so that the needle is on zero, and lock it down.

- Rather than sliding the indicator to the other end of the blade, rotate the blade forward and move the indicator forward.

- Take the reading. Chances are, the needle is not on the zero anymore.

- On the DeWalt tablesaw that Tamar is using, the blade housing is held in place with two hex bolts. Loosen the hex bolts.

- Tap the blade housing with a mallet in the direction that the blade needs to move. Tap the housing until the dial indicator is slightly past zero. It will move back slightly when you re-tighten the hex bolts.

- Rotate the blade back to the first position to verify that it is still at zero.

- Lock the hex bolts back down, and determine if the blade is zero-ed out at both front and back.

- Cut wood.

—Tamar Hannah is a woodworker in New Jersey with a YouTube channel, 3x3 Custom with some great videos illustrating great projects.