A Personal Fall Arrest System (PFAS) is an active type of fall protection which is designed to "catch" a person once he or she falls to minimize the potential for compounding injury.

The system must be designed and installed to limit the free fall to 6 feet. The system consists of an anchorage point, a body harness, and a connection device. This type of fall protection should be used only when the use of a passive fall prevention method (i.e. guardrails) has been determined to be infeasible. Guardrails are considered to be the primary means of fall protection in both construction and general industry.

Personal Fall Arrest Systems

The contractor should first consider passive systems for fall prevention because they provide barriers on the actual walking-working surface. Examples of passive fall prevention methods include guardrails, handrails, perimeter cables and hole covers. If planning for fall prevention still leaves a fall exposure, then a personal fall arrest system could be implemented. Personal fall arrest systems and passive systems are often used together. Consider the following when implementing personal fall arrest:

- Only a full body harness with a retractable or shock absorbing lanyard and locking snap hook can be used.

- Anchor points for tying off must be structurally sound.

- Employees need to be constantly tied-off when in the area of a fall hazard.

- All personal fall arrest equipment needs to be inspected according to the manufacturer's directions.

- The system needs to limit the free fall to 6 feet.

- Any additional hazards that could arise in the event of a fall such as swinging into structural beams need to be eliminated.

- A rescue plan needs to be in place in the event of a fall.

- Employees need to be trained in the used of the personal fall arrest systems.

General requirements for personal fall arrest systems

Equipment used in personal fall arrest systems are required to meet the following specifications. It is important to verify that the manufacturer has designed, tested and approved their equipment to meet the following.

Always read the instructions and the technical details which provide the capabilities and limitations of the equipment.

- Connectors shall be drop forged, pressed or formed steel, or made of equivalent materials.

- Connectors shall have a corrosion-resistant finish, and all surfaces and edges shall be smooth to prevent damage to interfacing parts of the system.

- D-rings and snap-hooks shall have a minimum tensile strength of 5,000 pounds.

- D-rings and snap-hooks shall be proof-tested to a minimum tensile load of 3,600 pounds without cracking, breaking, or taking permanent deformation.

- Lanyards and vertical lifelines shall have a minimum breaking strength of 5,000 pounds.

- Lifelines shall be protected against being cut or abraded.

- Ropes and straps (webbing) used in lanyards, lifelines, and strength components of body belts and body harnesses shall be made from synthetic fibers.

- Personal fall arrest systems must limit maximum arresting force on an employee to 1,800 pounds when used with a full body harness.

- Personal fall arrest systems must be rigged such that an employee can neither free fall more than 6 feet nor contact any lower level.

- A system must bring an employee to a complete stop and limit maximum deceleration distance to 3.5 feet.

- A system must have sufficient strength to withstand twice the potential impact energy of an employee free falling a distance of 6 feet, or the free fall distance permitted by the system, whichever is less.

- The attachment point of the body harness shall be located in the center of the wearer's back near shoulder level.

- Personal fall arrest systems and components shall be used only for employee protection and not to hoist materials.

- Personal fall arrest systems and components subjected to impact loading shall be immediately removed from service and shall not be used again for employee protection until inspected and determined by a competent person to be undamaged and suitable for reuse.

- Personal fall arrest systems shall not be attached to guardrail systems, nor shall they be attached to hoists except as specified in other subparts.

Fall protection basics

The first thing that needs to be recognized when using fall arrest systems is whether or not a fall arrest system is the most feasible type of fall protection.

- Can guardrails be used?

- Can safety nets be used?

- Can hole covers be used?

If any of these types of fall protection can be used, then a personal fall arrest system may not be the most feasible protection from falls.

An easy way to remember the 3 components to fall arrest systems is 'ABC.'

- Anchor

- Body Support (Harness)

- Connector or Fall Arrest Device (Lanyard or Retractable)

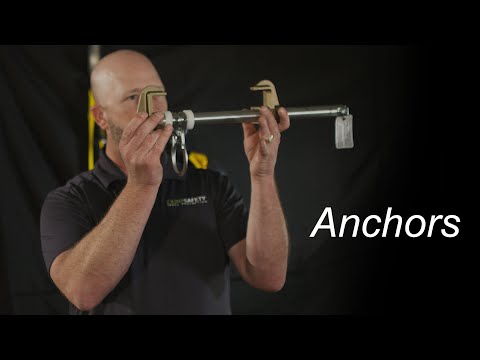

Anchorage Points

Anchorages used for attachment of personal fall arrest equipment must be independent of any anchorage being used to support or suspend platforms and must be capable of supporting at least 5,000 pounds per employee attached.

It is important to confirm the manufacturer's rating for any permanently mounted and installed anchor. The rating could be less than 5,000 pounds.

Identifying a proper anchor point is very important when using a fall arrest system. There are a number of fatalities each year where employees are tied-off to inadequate or improper anchor points.

Never use these as anchor points:

- Standard guardrail

- Standard railings

- Ladders

- Scaffolds

- Light fixtures

- Conduit or plumbing

- Rungs

- Ductwork or pipe vents

- C-Clamps

- Wiring Harnesses

- Rebar (except for positioning during framework)

- Roof stacks, Vents or Fans

- Another lanyard

- Any point which does not meet the structural requirements of OSHA Subpart M.

To keep the free-fall distance to 6 feet and to ease self-recovery, anchorages should be positioned overhead of the personal fall protection user at all times. Anchorage points should be carefully planned into the job to ensure continuous and complete protection during the work task.

Body support

A full body harness is a set of straps positioned around the shoulders, thighs, buttocks, and hips, typically designed to arrest a fall up to 6 feet.

This full-body harness features tool bags built into the system, available from superanchor.com

Full-body harnesses are designed to minimize stress forces on an employee's body in the event of a fall while providing sufficient freedom of movement to allow work to be performed.

Shock absorbers

Shock absorbers slow and cushion the fall, reducing the force of stopping the fall. In addition, they provide a means to determine in-service loading. All loaded lanyards (meaning they have been used to catch someone during a fall) must be destroyed and replaced.

image: superanchor.com

The shock absorber may increase the length of the lanyard by as much as 4 feet during a fall.

Refer to the label on the shock-absorbing unit to determine the maximum elongation. Allow for this extra fall distance when you include a shock absorber in your personal fall protection system.

Y-Lanyards

A Y-lanyard is a device that attaches two lanyard legs to a shock absorber and snap-hook, allowing workers to move horizontally from one area to another while continuously attached. This is done by attaching the first lanyard to an anchorage point, moving several feet, and then attaching the second leg of the lanyard to another anchorage point. The first lanyard leg is then disconnected and the worker moves on to the next convenient attachment point.

Some advantages of this system are bypassing obstruction while remaining attached, avoidance of attaching two separate lanyards, and handling ease. Some injuries have occurred from the snagging of the inactive lanyard leg on obstructions.

With planning, Y-lanyard applications can be converted to using pre-engineered horizontal lifelines which has advantages such as shorter potential falls, easier movement horizontally, and far few snap-hook connections and anchorage points to consider.

Self-retracting lanyard devices (Locking)

Self-retracting lanyard/lifeline devices with locking features are designed to arrest free falls within inches by eliminating the dangerous slack that can develop using fixed-length lanyards, much like a seatbelt. The line, cable, rope, or webbing extends or automatically retracts as the worker moves up and down. Overhead installation is critical for proper use in almost every situation.

image: superanchor.com

Self-retracting lifelines and lanyards which automatically limit free fall distance to 2 feet or less shall be capable of sustaining a minimum tensile load of 3,000 pounds applied to the device with the lifeline or lanyard in the fully extended position.

Self-retracting lifelines and lanyards which do not limit free fall distance to 2 feet or less, ripstitch lanyards, and tearing and deforming lanyards shall be capable of sustaining a minimum tensile load of 5,000 pounds applied to the device with the lifeline or lanyard in the fully extended position.

Snap-hooks

Snap-hooks used to connect workers to lanyards must be double acting.

Snap-hooks are hooks that have double action closure mechanism operable with the thumb and forefinger of one hand, comprises a rigid body, such as a forged hook, having a first end, a second end forming a curved nose, and a shank extending between the ends, the shank defining a front side facing the nose, and a back side facing away from the nose.

Unless approved by the manufacturer, snap-hooks must not be attached to each other or tied back onto its own lanyard.

Do NOT do this with snap-hooks, unless they are designed for it:

- Directly to webbing, rope or wire rope.

- To each other.

- To a D-ring to which another snap-hook or other connector is attached.

- To a horizontal lifeline.

- To any object in which its shape or dimension is incompatible in relation to the snap-hook such that unintentional disengagement could occur by the connected object being able to depress the snap-hook keeper and release itself.

Drop Force

No fall shall exceed a drop-force of 1800 lbs.

Drop force can be easily calculated using this formula:

(weight of the employee) x (distance of the fall)

Example: (200 lb worker) x (6 foot fall) = 1200 lbs. of drop-force

Locating anchor points above the worker's head will help reduce the drop force since the worker will have less free-fall distance than if the anchor point was at the worker's feet.

Fall Rescue Plan

After a fall, a worker may not be able to rescue themselves and may remain suspended in a harness.

A worker is at great risk of developing a condition known as "suspension trauma" if left suspended by a harness for a prolonged period. Suspension trauma is a serious condition and can even be fatal. Onset of symptoms of suspension trauma can occur as little as 5 minutes after a fall. A rescue plan should be in place to retrieve a suspended worker as soon as possible after a fall.

- Make sure ladder trucks will be able to reach hanging workers, or plan ahead for other ways to rescue them.

- Be sure medical and rescue teams will get there fast if needed.

- Products are available to limit the risk of suspension trauma after a fall. Suspension trauma straps are compact units worn on the harness.

Personal fall arrest systems and components subjected to impact loading shall be immediately removed from service and shall not be used again for employee protection until inspected and determined by a competent person to be undamaged and suitable for reuse. The equipment in question is typically sent back to the manufacturer for inspection.

Employee Training

- The employer shall provide a training program for each employee who might be exposed to fall hazards. The program shall enable each employee to recognize the hazards of falling and shall train each employee in the procedures to be followed in order to minimize these hazards.

- The employer shall assure that each employee has been trained, as necessary, by a competent person qualified in the following areas:

- The nature of fall hazards in the work area.

- The correct procedures for erecting, maintaining, disassembling, and inspecting the fall protection systems to be used.

- The use and operation of guardrail systems, personal fall arrest systems, safety net systems, warning line systems, safety monitoring systems, controlled access zones, and other protection to be used.

- The limitations on the use of mechanical equipment during the performance of roofing work on low-sloped roofs.

- The correct procedures for the handling and storage of equipment and materials and the erection of overhead protection.

- The role of employees in fall protection plans.

- The standards contained in subpart M.

- Certification of Training The employer shall verify compliance with paragraph (a) of this section by preparing a written certification record. The written certification record shall contain the name or other identity of the employee trained, the date(s) of the training, and the signature of the person who conducted the training or the signature of the employer. If the employer relies on training conducted by another employer or completed prior to the effective date of this section, the certification record shall indicate the date the employer determined the prior training was adequate rather than the date of actual training.

- Retraining When the employer has reason to believe that any affected employee who has already been trained does not have the understanding and skill required by paragraph (a) of this section, the employer shall retrain each such employee. Retraining is required—but are not limited to—situations where:

- Changes in the workplace render previous training obsolete; or

- Changes in the types of fall protection systems or equipment to be used render previous training obsolete; or

- Inadequacies in an affected employee's knowledge or use of fall protection systems or equipment indicate that the employee has not retained the requisite understanding or skill.

Addressing and reducing risk

Working near unprotected roof edges, roof and floor openings, scaffolds, ladders, structural steel, leading edges, and open shafts can expose workers to potential fall hazards when no passive fall protection is in place.

Falls from height typically result in severe injuries or death. A PFAS is a type of personal protection equipment for fall protection designed to "catch" a person once he or she falls to minimize the potential for severe injury.

Risks are reduced and controlled by the personal fall arrest system which is designed to prevent the employee from hitting the ground. If an employee has fallen and the personal fall arrest system has been activated, the employee has two options.

The first option includes self-rescue. The second option includes the employee being rescued by others. Rescue can be accomplished through a variety of methods including mobile cranes, ladders, scissor lifts, and articulating booms.

Manufacturers of personal fall arrest systems say when used properly, there is a reduction in the risk of injury or death due to a fall from elevation when using a PFAS.

OSHA believes that the proper use of personal fall protection systems can protect employees from injury and death due to falls to different elevations.

Additional Considerations:

Swing Hazard

Dangerous pendulum swings may result when a worker moves horizontally away from an anchor point and falls. The arc of the swing may produce significant speed that can propel the worker into an obstruction, causing injury or death. Swing hazards can be reduced by ensuring that anchor points are overhead of the worker at all times.

Fall protection designs should include multiple overhead anchor points that employees can access when moving to a new position. Horizontal lifelines also provide continuous overhead attachment points. The force of the swing can be reduced by raising the height of the anchor point, reducing the angle of the arc.

Equipment Mixing and Mismatching

Employers and employees must both realize that components of a system may not be interchangeable. No component of a fall arrest system should be substituted or changed unless fully evaluated and tested by a competent person or the equipment manufacturer. When purchasing a fall protection system, it is best to purchase a complete system from a reputable manufacturer or authorized dealer.

Equipment Inspection and Storage

Fall protection equipment should be inspected frequently and before each use to ensure damage has not occurred. Hardware should be inspected for corrosion, burrs, sharp edges, chemical damage, too much wear, discoloration, deformation, and cracks.

Software should be inspected for fraying, unsplicing, unlaying, kinking, knotting, roping, broken or pulled stitches, abrasion, chemical damage, or sections that are too old, too worn, or too dirty. Any equipment found with excessive damage should be marked "Do Not Use" and removed from service. Follow manufacturer's instruction on inspecting.

Fall protection equipment must be stored correctly and according to manufacturer's instructions. Store equipment away from heat, light, dampness, oil, chemicals or other damaging conditions.

Where to buy fall protection equipment

Fall protection equipment for residential construction classified by the type of equipment and the phase of construction can be found on this Washington University website: http://www.ot.wustl.edu/fptech/homepage.htm

Super Anchor Safety

To obtain information, visit http://superanchor.com or contact 1-855-301-4575 chrisl@superanchor.com

Rigid Lifelines

To obtain information, visit http://www.rigidlifelines.com or contact 1-800-869-2080 info@rigidlifelines.com

3M Fall Protection Products

To obtain information, visit http://solutions.3m.com or contact 1-800-243-4630

MSA Safety

To obtain information, visit http://www.msasafety.com or contact 1-800-672-2222

Guardian Fall Protection

To obtain information, visit http://www.guardianfall.com or contact 1-800-466-6385

Safety Pole

To obtain information, visit http://safetypole.com/ or contact 1-805-857-4256

This article is by Mark Fullen and Kristen Savage of West Virginia University and is lightly edited and reprinted with permission from NIOSH.