7 less common (but potentially problematic) shower waterproofing situations

Over the last couple of weeks we have been rolling out a mini-series on shower waterproofing based on the Best Practices presentations BOWA, a design/build/remodel company on the DC area.

The first was Weak Links in the Shower: 4 Shortcomings in Waterproofing Logic, the second was 5 Step Waterproofing System: Best Practices for Tile Showers. This is the third, and final, element of that collection, covering slightly atypical shower scenarios. But not atypical enough to not include them.

1. Slot drains:

- Nice look, slick installation

- You may need to frame the shower to fit the drain, so read the manual before ordering. There are a lot of options, but there can also be a significant lead time with them, so read the manual before ordering, make sure you know what you are getting and need to do to prepare for it. Schluter and Noble make their own drains to integrate into their systems.

- Single layer, no redundancy. Many are not bi-level drains, so it critical to get the waterproofing right. This is the only layer.

2. Steam showers:

Steam showers must contain all the steam within the room—which means that there will be a lot of steam in the room—which means that the waterproofing needs to go all the way up the walls and across the sloped ceiling.

- Water vapor will penetrate the tile/stone. Must have a vapor retarder/waterproofing.

- Full Kerdi, including ceiling, with 2-inch overlaps is a great option and has worked for BOWA.

- Liquid-applied waterproofing membrane is not usually a vapor barrier, so do not use only liquid waterproofing in steam showers.

- Slope the ceiling two inches per foot—or more. I saw a set of instructions that said 4 inches per foot. A “roof” type design with two slopes is one way to make enough room.

- Install a fan inside the shower or a remote-mount fan with an inlet in the shower—for mildew control. Fans with steel bodies can drip rusty water if installed toward a cold attic. A remote fan with a plastic grille is better. There are fans that are substantially plastic, which are probably fine.

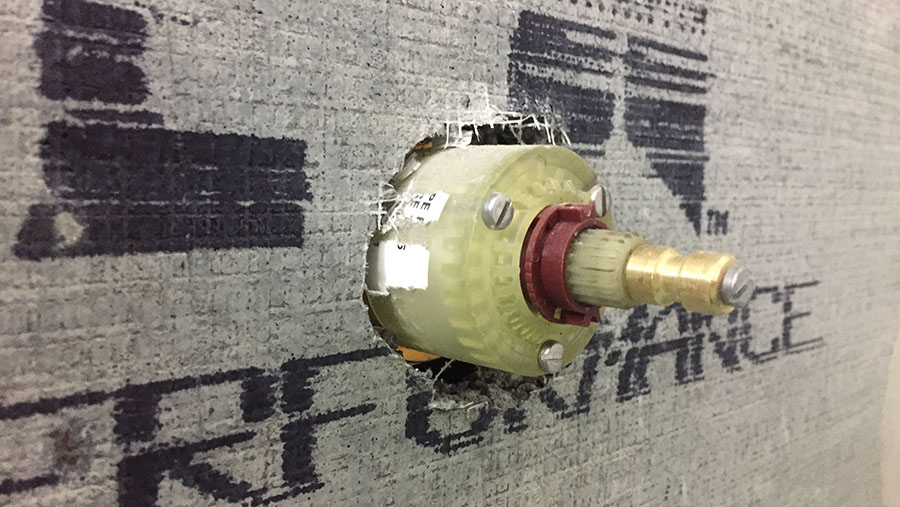

3. Valves: a common-enough leak spot worth mentioning

Valve openings should be sealed at waterproofing stage if possible. Kerdi has some gasket-like fittings, but they never seem to fit the vales. Ever.

OK, not always. The small ones are perfect for shower heads and tub spouts.

After the tile is on, you can caulk the hole in the tile around the valve, and caulk the top 3/4 of the escutcheon, leave bottom open for drainage.

4. Drywall connection: where drywall ties in to tile backer.

The main problem is rust at the corner, the solution is to use vinyl corner bead. Other problems and solution:

Problem: Mushy compound. Solution: Durabond.

Problem: Moldy drywall. Solutions: full Kerdi system or cement board everywhere water will be.

5. Roll-in shower

Where we are, Fairfax county, the code requires a minimum 2-inch slope from drain to curb, so we have to get a code exception to build a roll-in shower unless it is big enough to allow enough slope over the area. The exception is easy to get, but it is important to ask for it ahead of time.

6. Tub in shower—deck-mounted tub will not work

Sometimes this happens when people want a big whirlpool tub to go wall to wall, like with a smaller tub. But small wall-to-wall tubs have flanges.

Tubs must have flanges to integrate into walls. Add-on kits may work. Or they may not. Manage the waterproofing at the front edge, too—use two layers up waterproofing up the front face, and under the tub, if possible.

7. Window in a shower

Like a niche or a ledge, but sloped differently. Under the window, slope out. Inside the window, slope in. Slope both directions so that water drains toward the source of the water. Slope out for rain, slope in for shower spray.

Two more items about windows in showers:

- Connect the shower waterproofing to the window pan.

- Caulk is iffy- user layers and slope as primary defense

Bonus tip:

When setting marble in a shower, use plastic shims, not wood. Turns out when the wood gets wet, the tannins booked through into the marble.

Previously in this series we looked at Weak Links in the Waterproofing Process and 5 Step Waterproofing System: Best Practices for Tile Showers.

—Doug Horgan is a Vice President of BOWA, a Design, Build, Remodel, and Consultation company with offices in McLean and Middleburg, Virginia. Doug is also one of ProTradeCraft's technical advisors.