One cold spot on the house is where the edge of a concrete slab is exposed to the outdoors. Because outdoor air is a lot colder than the ground in winter and hotter in summer, this thermal bridge is more like a thermal runway.

We have covered two ways to Insulate monolithic slabs—for hot places and cold ones— but when you add brick the picture, things get a little more complicated.

First, you need a shelf to support the brick. This shelf can be a piece of angle iron bolted to the foundation, or it can be a cast-in-place step.

Step by step:

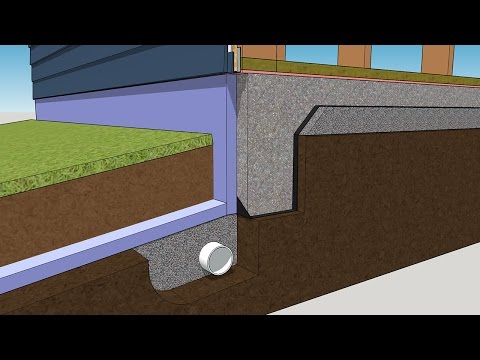

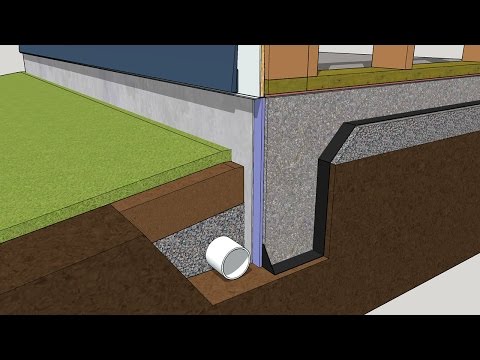

- A bed of compacted gravel caps the ground under the slab as a capillary break and stable base for the concrete.

- Lay a plastic vapor barrier atop the gravel and wrap the edge of the plastic up to grade as a barrier to ground moisture.

- Pour the slab, adding a shelf to the outside. It is best to slope the shelf away from the house. Also, make sure it is deep enough to support brick, at least an inch of drainage space, and room for ANY exterior insulation you will add.

- Install a drip edge flashing, preferably stainless steel or copper. It is best to tuck it behind the wall sheathing if possible, but it at least should be lapped under the house wrap.

- Install the exterior insulation. If you are not adding exterior insulation, add another layer of building paper.

- Call in the bricklayers. As they lay that first course of brick, make sure that they add weep holes every couple of feet along the bottom course. Otherwise, water that gets behind the veneer will not be able to escape. Weep holes and flashing with a kicked out edge give it a place to go.

This collection of details should be all you need for a dry slab, but before putting down a floor, it makes sense to use a waterproofing membrane or masonry paint.

With the water management system in place, focus on slowing the heat flow. Lay wooden sleepers on the slab every 24 inches with strips of rigid insulation between them. Cover it up with subfloor panels, and you are on your way to a slab assembly that ain’t scared of the weather.

—Details based on The International Masonry Institute details with additional technical assistance from Harrison McCampbell, AIA, in Nashville, TN