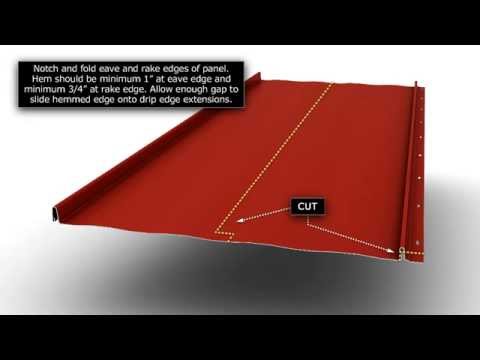

How to bend two basic shapes on a Tapco brake

One of the simplest bends to learn when working with coil stock sheet metal is hemming an edge. Going one step further, you can create a seaming connection.

How to hem the edge of sheet metal

- Use the front of the brake as a guide to align the edge of the sheet metal. This will yield a consistent 3/4-inch hem.

- Fold the brake up as far as the hinge will allow

- Remove the workpiece and drop it into the hinge pocket, lifting up on the hinge to pull it into the top of the banana-shaped slots, and bend up with the hinge handle. This closes the bend from the previous step.

How to form a hem into a seam:

- Reinsert the workpiece into the brake until out outer edge of the hem is aligned with the outer edge of the brake

- Bend up as far as you can

- Repeat the process of lifting the hinge and closing the bend.

These are two critical bends that every roofing, siding, and remodeling professional needs to know.