Mike Day, a concrete flatwork contractor in North Monmouth, Maine, is pouring an arced walkway, a curved entry pad, and a patio slab at a new construction home. This video focuses on the arced walkway and curved-edge concrete slab out front.

Learn how to estimate concrete for a radius slab.

Essential concrete pouring tips in the video:

The edging is PVS trim stock. PVC trim is durable, reusable, and bends very easily.

Forms are set to grade rather than above.

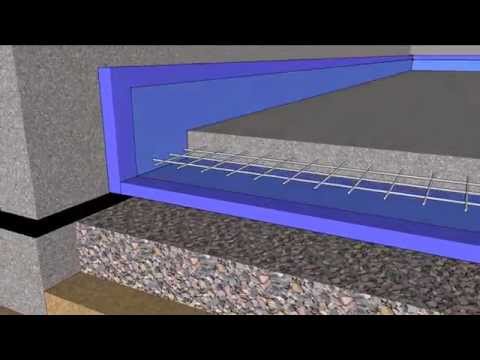

Pull the wire mesh up as the concrete is poured; this will allow rocks and aggregate to move under the wire mesh, holding the mesh off the ground, even when workers walk through the wet slab.

Notes on the concrete mix

In addition to the wire mesh, Mike also uses fiber mesh as a double reinforcement.

The mix is 4,000 psi 3/8-inch aggregate for stamped concrete, which this walkway will be.

He also adds 5% air entrainment to the mix to offset the effects of freezing and thawing. The surface is also sealed to prevent water from soaking into the concrete and freezing.

To see why the suitable concrete mix matters, read about what happened to this project.

Division of labor on the concrete pour

One person pulls up the wire mesh, two people spread the concrete, and one screeds the top behind them.

The pouring portion of the crew moves over to the next pour, the entry pad, and the finisher bull floats the curved walkway.

There is also a patio out back that was poured first, explaining why there are five people on the crew.

Slab edge tips

The edges are tapped with a mag float to vibrate the concrete into small gaps for a more consistent slab. The small 3/8 aggregate makes it easy for the concrete to fill gaps. Also, this slab will be butted up with an asphalt driveway and grass.

Mag-float the edges before screeding to keep concrete chunks off the top of the forms and to keep the edges clean.

As they near the end of the walkway slab, they stop pouring and screed the pad. This helps avoid getting too much concrete in the forms, which would need to be shoveled out.

Bull float along the long direction rather than directly across the slab to leave fewer float lines to finish out.

You can screed the slab level by using the floated edges as a guide -- this is done on the entry slab.

For more on edging a concrete slab, watch this and this

Finishing Tips

At an entryway like this one, it often makes sense to cover finished surfaces with plastic to avoid splatter, but in this case, the crew is just being careful because *someone* forgot to bring plastic.

Again, as the concrete is poured into the form, the edges are mag-floated.

The grade was shot with a laser and marked with a chalk line. Mike floats the concrete level to that chalk line.

The slab is sloped away from the house to push water away as soon as it lands there.