UPDATED: 10/11/24 (updated text formatting and removed YouTube videos that had disappeared—poof)

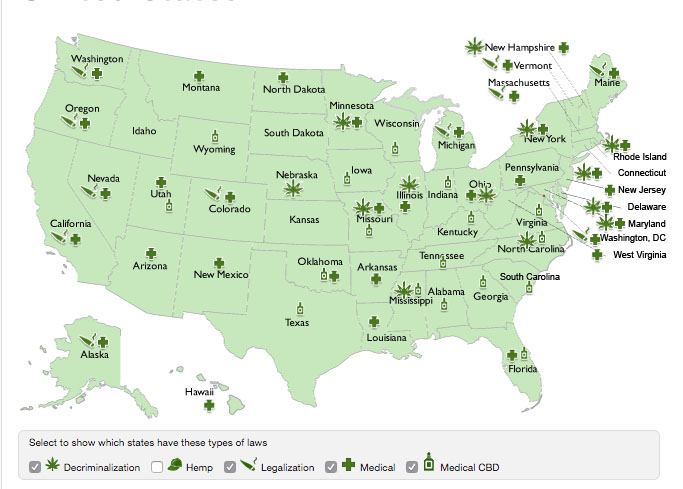

Marijuana is now legal in eight states and the District of Columbia. It is decriminalized in 15 more states, and medical marijuana is legal in 29 states. There are only five states where it is totally illegal like it was in the 20th century.

Sooner or later, if you are a remodeler and live in one of the 41 states on this map from NORML, you will be asked about building a grow room. If asked, you should have intelligent answers to your customers' questions. And some questions of your own.

We aim to arm you with them. The good news is that building a grow room is similar to building a bathroom—it includes plumbing, electrical, ventilation, and waterproofing.

It also includes security and may include carbon dioxide tanks or generators. It will undoubtedly include your local building inspector; clear communication may be one of your sharpest tools.

The other good news is that these things make a small job MUCH more profitable.

Sections in this Guide:

- Bird's eye view

- Space Planning

- Ventilation

- Lighting and electricity

- Bulk water issues/waterproofing

- Fire and health safety issues

- Code enforcement

- Security considerations

- Sources

Bird's eye view of marijuana grow rooms:

High-intensity light needs to cover plants as efficiently as possible. The plants give off a lot of moisture and require a lot of moisture, so there are humidity issues.

Because watering plants requires bulk liquid water, there are water management issues.

The high-intensity lights draw a lot of power and give off a lot of heat, so there are space efficiency and fire issues.

Marijuana is attractive to criminals, so there are security issues.

Even when you get past the engineering, science, and construction, you still need to communicate with your building inspector. Because all politics are local, and building inspectors are exactly like any other person (unique individuals) it may be even more important to have a clear line of communication (and a good relationship) with your building inspector.

This article is meant to point you in the right direction for more information, it is not meant to be a comprehensive how-to manual.

It is more like a review of my initial research into the topic than a final report.

Fire and health safety issues:

Upgrading the electrical may need more than the main panel and a sub-panel. Ask your power company to inspect and upgrade the service entrance.

From FireEngineering.com:

"Electrical demands to serve the numerous grow lamps typically operating at 1,000 watts each are very high. Several fires have occurred as a result of the melting of the overhead electrical service. Although the inside electrical system was sized correctly and inspected, the electric utility service from the transformer was never upgraded.

A closer working relationship with the electric utility solved this problem."

Other fire issues are from heat buildup: the surface temperature of these lights can reach 500 degrees Celsius.

Whether your inspector will want an extra layer of drywall as a fire barrier may vary. But it may be a good idea to include in the estimate.

Propane CO2 generators are standard in commercial grow rooms but are less likely to be used in residential rooms. Propane CO2 generators burn flames, so they require heat shields. There is also a risk of CO2 poisoning. Be careful when considering this option for a system in a house where people live.

More from FireEngineering.com:

"Nationally, CO2 systems have become a concern because of recent deaths from beverage dispenser leaks; the 2015 International Fire Code has new code language addressing these systems.

However, CO2 enrichment systems found in marijuana grow rooms are different in that they intentionally flood the grow rooms with CO2. These systems present potential asphyxiation hazards and are regulated by operational and system installation permits issued by the DFD Fire Prevention Division.

Growers typically keep CO2 levels in rooms at less than 1,500 parts per million (ppm). For context, the Occupational Safety and Health Administration (OSHA) eight-hour permissible exposure limit (PEL) is 5,000 ppm.

These systems are required to have a local CO2 detection system in each enriched room set to alarm at 5,000 ppm and a master control valve to shut off the flow of CO2 at the source."

Bonus tip:

A handy way to make fire extinguishers accessible, visible, and protected: Fire Safety on the Jobsite

Code enforcement could be a crap shoot

As we alluded to in the introduction, the ultimate authority could be your building inspector. And just because it is legal in the state does not mean that a grumpy inspector will make it particularly easy on you.

A question posted to a code enforcement forum asked fellow building officials that if they were in a state such as Colorado, where marijuana is legal, what would they require on the permit?

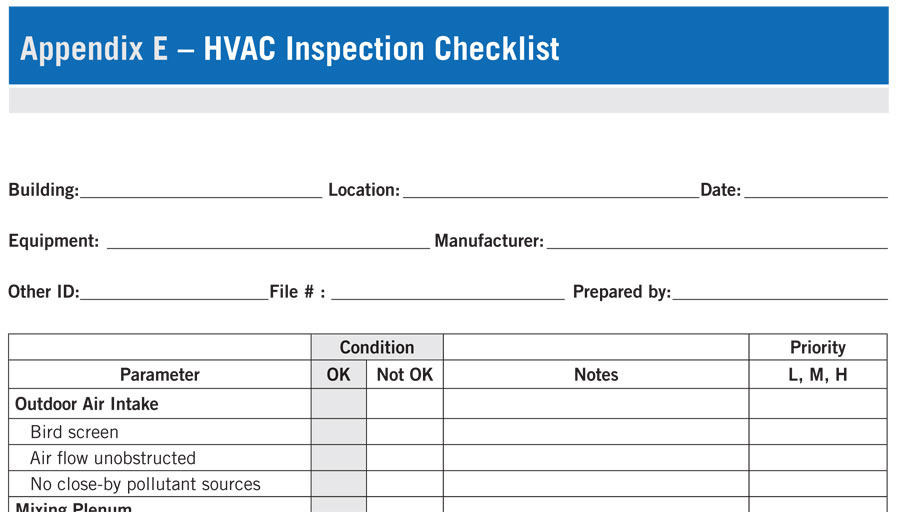

Q: Aside from your viewpoint on marijuana, if someone where to come to you and ask for a permit to install a grow room in one of their bedrooms, what would you require on the permit? The issues I see are electrical loads and ventilation (high humidity = mold).

Some jurisdictions do not even allow agriculture growing in residential units (San Francisco, Ripon), but until we have an ordinance as such, I would like some input.

—Dean R via Building Code Discussion Groups

- Complete electrical load calculations per CEC 2007,

- Calculations demonstrating compliance with 2005 Calif. building energy efficiency standards

- Change of use from R-3 to U for the room,

- Plans detailing the required fire barrier per the 2007 CBC

- A complete HAZMAT assessment

- Fire hazard response plan drawn by a registered fire protection engineer and submitted to the Fire Marshall

- Fire sprinkler plans

- Complete plumbing plans including details of the membrane penetration or through penetration fire stop system

- Seismic restraint plan for the grow lights including calculations prepared by a California registered structural engineer

- Written plan and contract with an approved mold consultant including at least yearly testing

- A written plan from a registered arborist for spacing of the plants to provide a minimum exiting width

- A written list of all chemicals used in the process and maximum quantities to be stored

- MSDS sheets for all chemicals

- A complete mechanical plan including an engineered smoke and heat venting plan

- A written opinion from a licensed medical professional expert in the field detailing the safe height of the mechanical discharge above grade plane

- An OES emergency discharge plan to be approved by the State Department of Emergency Services

- A letter from the Department of Fish and Game stating that there will be no deleterious effects to birds, gnats, midges, protected owls or Swensons Hawk from an accidental discharge of noxious smoke from the emergency smoke control system

- A fire protection panel shall be installed at a readily accessible location approved by the Fire Marshall

- The room shall be posted NO SMOKING OR OPEN FLAME PERMITTED in a location or locations that will remain visible when the plants are in full foliage

- Lighted exit signs shall be provided per the 2007 CBC Chapter 10 and the project shall be provided with emergency lighting sufficient to obtain 1 foot candle at floor level in all portions of the exit system.

—Cliff Young_modesto

Clearly, there is quite a difference in how one building official may consider your request and how another might. If you want to be profitable, make sure to know this information up front.

Tip: It is probably best to schedule the meeting for after lunch—you don't want to catch the building official on an empty stomach.

Security considerations: Leaking light and odor

Security is a big deal, even in states where marijuana is legal, because criminals break into houses to steal things.

In setting up the room, it is important to seal windows from light leaks, because the lights are bright and they are often turned on at night. Part of covering the windows may mean camouflaging them with a screen, curtains, or similar so they appear closed from the outside.

It is also important to seal light leaks from inside detection. The homeowner may not want to advertise their growing operation to guests at dinner parties.

Odor control can be accomplished with charcoal filters, as mentioned in the ventilation section. But it is worth mentioning here for checklist purposes.

Another security measure that could increase the price of the job (and the amount of fun) in the project would be to include hidden doors:

Structural questions:

- Is the typical 10 lb dead load and 40 lb live load (or 30 lb if bedroom) enough to hold all the pots, soils, water, etc.?

- Is the roof/ceiling structure strong enough to support the lights and ballast?

Four steps to space-efficient and energy-efficient grow room layout:

- Space the lights to cover the floor area with equal intensity.

- Build enough 4-foot x 8-foot tables to cover the floor entirely.

- Add small casters to the bottom of each table leg.

- Remove one table.

Jorge's point: you don't need an aisle to walk between every table because there is only one of you. If the tables can roll, then all you need is a single aisle that moves.

Ventilation: exhaust, supply, and mixing airflow

A carbon filter is attached to an in-line exhaust fan. Photo from Alchemia.

Grow rooms have very high humidity due to transpiration from the plants and evaporation from overflow trays. Like a bathroom or any other wet room, it is important to exhaust moist air to avoid mold problems. When you exhaust a lot of air from a reasonably tight room, it's a good idea to introduce make-up air. You can do this with a separate supply fan or use an integrated unit such as an energy recovery ventilator (ERV) or heat recovery ventilator (HRV).

When exhausting, most people add carbon filters (above) to control odor.

In addition to exhaust and supply, most grow rooms have constant (or frequent) circulation from floor fans or box fans hung from the ceiling. This air circulation dissipates heat from the bulbs and strengthens the plant stems. Plug-in box fans are not part of the ventilation system, but the plugs need to plug into outlets, so consider this during the electrical plan.

Some builders add AC to grow rooms to cool and dehumidify them in one step, and the condensation can be used to water the plants. I don't want to go into that kind of depth here, so I'll leave it at this: If you want to use the existing HVAC system to condition the space, consider how adding thousands of watts of lights (yes, thousands—see below) will affect the Manual J load calculations.

It might be a good idea to ask an HVAC professional or energy rater to do the calculations.

More ventilation information:

- Ventilation for Marijuana Grow Rooms—Alchemia Blog

- Whole-House Mechanical Ventilation: Exhaust, Supply, Balanced, and Backdrafting—ProTradeCraft

- HRV or ERV?—GreenBuildingAdvisor.com An ERV or HRV may be a good way to balance the supply, exhaust, and temperature.

- What Is The Ideal Temperature For Growing Marijuana Plants?—The Weed Blog

[Insert ducts-in-a-row pun here]

Regardless of what types of fans you buy and install—for grow rooms or not—ductwork installation and duct design are critical factors in whether the fans actually move air.

Many of the YouTube videos on grow rooms illustrate terrible duct design and installation techniques—some show 180-degree bends in flex duct which is hung from the ceiling. This is like adding 140 feet to the duct run. For every 180 degree bend. That's a lot of ductwork.

- 18 Ways to Get Better Performance From Flexible Ducts—Be economical, direct, and don't get kinky

Lighting and electricity

Lighting and electricity

According to High Times, marijuana cultivation accounts for up to one percent of the total energy consumption in the US. That is probably because of the lighting equipment: 1,000 watt metal halide (HID) and 800 watt sodium vapor (HPS) bulbs are the norm.

These are the same bulbs that used to be in streetlights and security light fixtures on industrial buildings. They are basically really big incandescent bulbs that give off a lot of light and a lot more heat. These bulbs require a large ballast.

Incandescent bulbs have been phased out of residential use in favor of more energy efficient options like CFLs and LED. While LED lights have shown great improvement in recent years, for indoor grow rooms, the bulk of the work is still done with the energy wasters; at least it was in late 2014 when this lighting review was done by High Times:

But, more streetlights are being swapped out for LED versions that are just as bright, so that may be the case with grow lights, too.

Using the energy hogs means that you may need to add a subpanel, update the service entrance, or both. And it means a lot of unwanted heat, which is bad for plants and worse for fire danger.

Other electrical questions to consider:

- Should all the outlets be GFCI protected?

- Should there be dedicated circuits for each ballast?

The other little hitch to this electrical project is that the electrical components should usually be hanging—or at least off the floor. Water on the floor is a distinct possibility and water does nor play well with electronic ballasts. Also, as noted above, because the floor space is so important, growers usually try to hang extra equipment in corners, above lights, and out of the way.

Bulk water issues

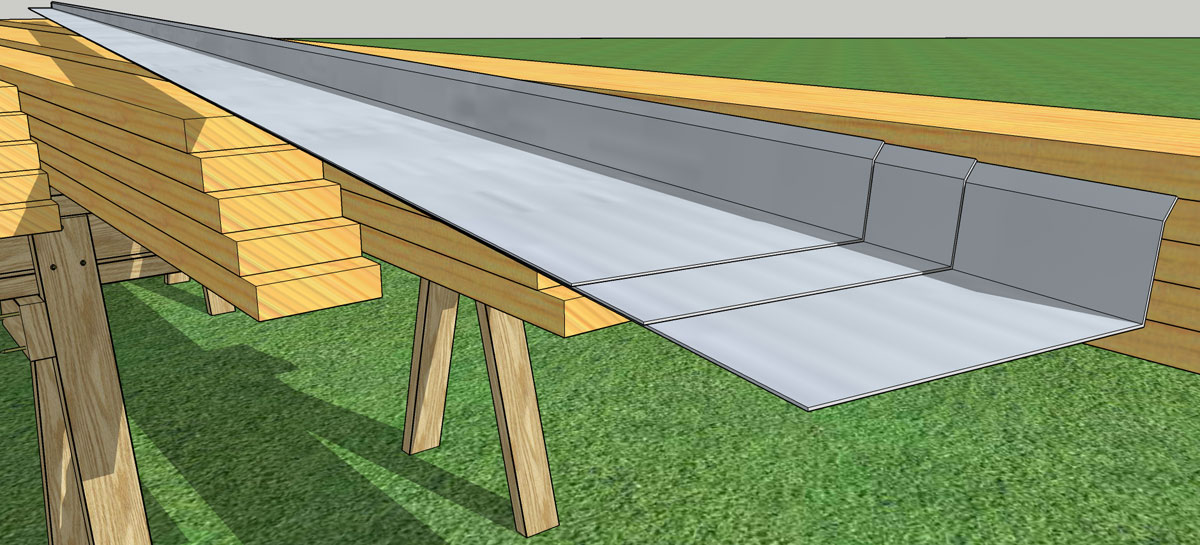

Like any other wet room, a grow room needs a bulk water plan. Plumbing supply lines to sinks should be stainless steel. Some sort of floor drain, with waterproofing membrane, and tile makes a robust floor system that will handle most water mishaps.

Plastic, prayers, and a ShopVac is another way to go, but we don't recommend it. And your building inspector might not approve it.

Waterproofing is really nothing new for most remodelers, so follow your best practice procedures, and double-check the details.

- Moisture Management Guide: 3 Design Rules—ProTradeCraft

Waterproofing walls and floor with liquid paint-on membrane

ED's note: Before the videos were removed, I noted that one of them appeared to be a pirated version of a DVD made by High Times magazine. I also noted that I had sent a note to High Times telling them about it. I guess HT asked the pirate to take it down.

The videos generally outlined the importance of electricity, ventilation, plumbing, and water management.

But most projects begin with space planning and design. Space planning in the case of grow rooms is very important because floor space and lighting are inextricably linked.

The lights can only cover a certain amount of space—a light bulb in a warehouse is much less effective than that same light bulb in a closet—so space directly below the lights is premium real estate.

Light intensity is the key, and intensity drops off exponentially with distance from the bulb. For that reason, either the bulbs or the plants (or both) must be able to move as the plants grow.

Space Planning with Jorge Cervantes

How to get the same lighting efficiency in half the space: use casters. It is important not to waste light and space for more than just maximizing the crop yield. The lights are expensive to run.

This video shows a larger room than most remodelers will ever need to build, but it illustrates how to think about the space you need to convert and the importance of light distribution.

Sources:

- http://www.thebuildingcodeforum.com/forum/forum/residential-non-structural-code/residential-building-codes/10400-irc-indoor-grow-rooms

- http://bcdg.hoop.la/topic/permitted-grow-rooms

- http://mrsc.org/getmedia/56A3606A-F3CF-455B-AC00-CA4BD0C300CD/thomas.aspx

- http://www.fireengineering.com/articles/print/volume-168/issue-2/features/fire-codes-and-standards-denver-s-legalized-marijuana-industry-and-the-fire-code.html

- http://norml.org/states

- http://www.alchimiaweb.com/blogen/ventilation-marijuana-growrooms/

- http://www.theweedblog.com/what-is-the-ideal-temperature-for-growing-marijuana-plants/

- http://www.hightimes.com/read/grow-lighting-led-vs-hps

- https://youtu.be/CKzpKNo0L5Q?list=PLU1aP_Y9qGOwyVTAqZgCrYiGi1bkOtYeA

- https://youtu.be/CKzpKNo0L5Q?list=PLU1aP_Y9qGOwyVTAqZgCrYiGi1bkOtYeAhttps://youtu.be/o-CBg7XTBe0

—Dan Morrison is the editor of ProTradeCraft.