I have been doing energy audits for about six years now. I enjoy studying building science and putting it into use to solve problems for customers. The only problem is that the work is typically attic Insulation in the attic or basement insulation in the basement, which are two miserable and challenging places to work.

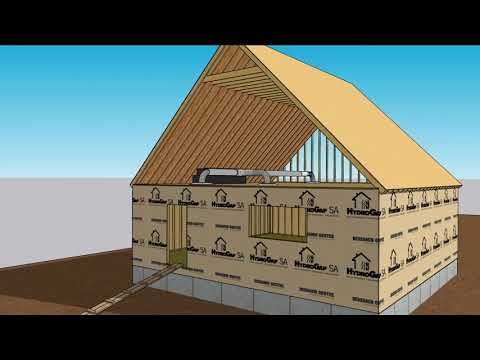

A drawing of a roof/wall ventilation scheme is easy to understand and looks easy to install. On paper, it is.

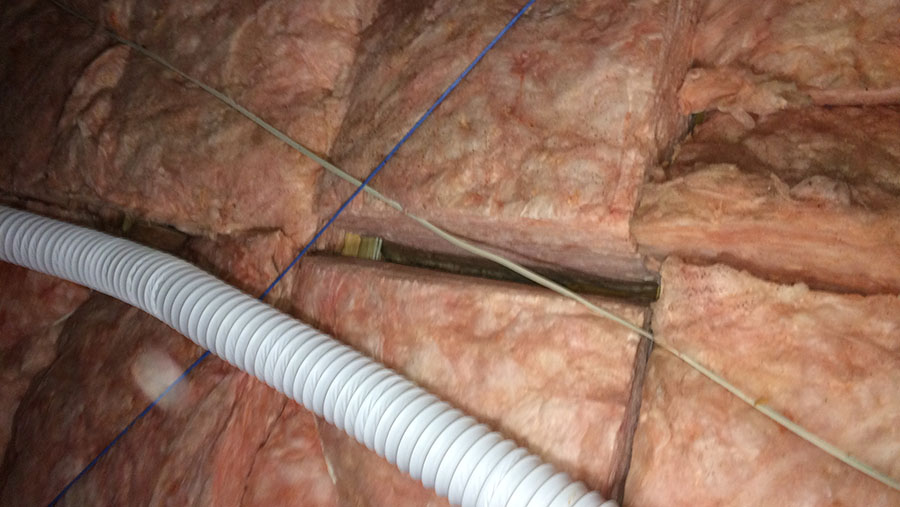

In practice, attic Insulation is anything but easy. Lying on rips of plywood across ceiling joists and reaching deep into bird’s mouth cavities fishing around for fibrous insulation—usually pushing against your face, arms, and shoulders, is no picnic. It is often hot and always dusty.

Even in cold weather, you will be covered with sweat. #TheStruggleIsReal

Some attic Insulation jobs cannot be done this way

That describes an attic with a steeply pitched roof. But many things can complicate the job. Low pitch, AC units and air handlers, water heaters, ducts, wires, and pipes—pretty soon the job may not even be possible to do. There may simply be too many obstacles to seal the attic at the floor. In such cases, it may be worth thinking about turning the attic into an unvented attic, conditioned attic by spraying foam insulation into the rafter bays. This can get complicated and is far beyond the scope of this article. There are many types of foam and many needs based on your climate zone.

When tightening an existing house, the first area to improve is the ceiling plane along the thermal boundary. Cathedral ceilings are typically not accessible from above; so flat ceilings with vented attics above are where the work is.

The work begins by tightening the ceiling and finishes with extra insulation—not necessarily because the existing R-value is too low, but because the quality of the installation is substandard. Poor installation quality can be due to obstructions, but it can also be due to sq.ft. pricing—which I know from experience leads to higher production and lower quality.

Regardless if the install quality, it is common for an inspector to look only at the R-value on the package and not the quality of the installation.

Older attics have probably had people crawling through them off and on for years; many areas of the insulation will be packed down, tore up, or pulled out.

My general approach to making an unconditioned ventilated attic work best has three main points:

- Air seal all penetrations and possible leakage paths.

- Then insulate to at least the current energy code, not only to the proper R-value but also to Grade I quality.

- Ventilate the attic 1 sqft per 300 sqft of attic floor space, balance at ridge and soffit areas.

Sealing the ceiling so the attic insulation can work

Before I add insulation, I seal the attic. There are a lot of holes, gaps, and cracks that leak a lot of air. Some holes are apparent, like attic hatches or folding attic steps. Others may not be obvious, like the continuous gap along partition walls. Lightboxes, bath fans, recessed lights, and wire holes may look like little things, but they add up to a lot of leaks.

I sketch the floor plan and include all penetrations that I can see from below, and orient this diagram with the attic access hole so that when I am in the attic, I have a map of everything that needs air sealing.

Just because there are attic vents, doesn't mean the attic is venting

I start by assessing the existing ventilation. I look at the ridge vent both from the inside and the outside. Potential concerns that I look for are a very low-profile ridge vent outside and not enough of the sheathing cut away inside. Both of these conditions obstruct air movement.

I also look at the soffit vents—closely. I have seen some older homes with soffit vents installed directly over solid wood soffits with small holes cut.

The IRC calls for 1 sq ft of ventilation for every 300 sq ft of attic space, balanced between the ridge and soffits, but in real life it seldom is. Insulation may be blocking the bottom, or there may not be enough vents in the soffits.

The ventilation space along the ridge may not be sufficient. Fixing either of these is not easy work. My company only addresses the work inside the attic with the occasional exception of tearing out and replacing some soffits. If a ridge vent needs to be installed or improved, I recommend a roofing contractor.

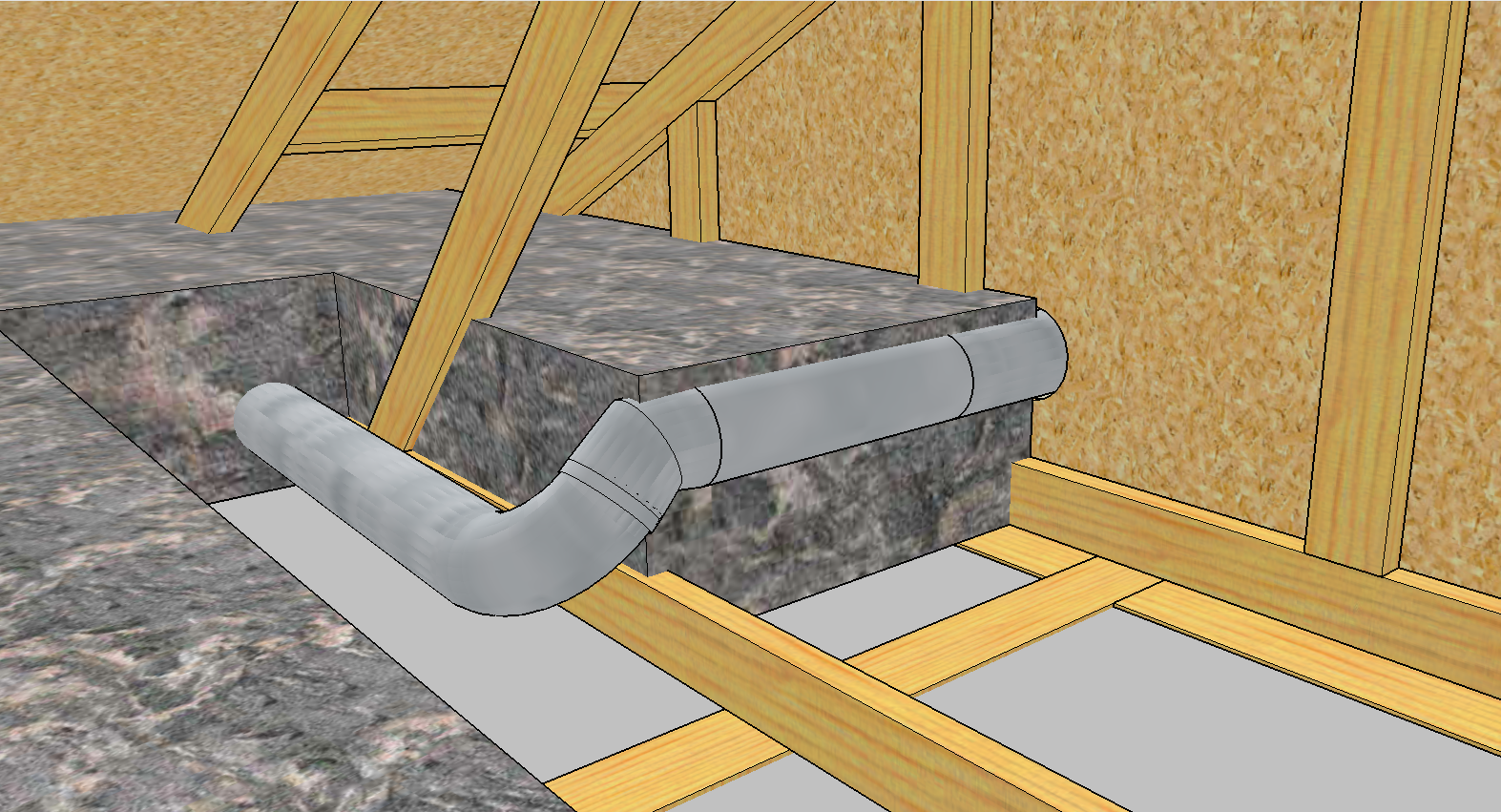

I concentrate on improving the ventilation where the rafters sit on the exterior walls. I want to open up this pathway so air can smoothly flow in and push warm, moist attic air out the ridge. I also want to prevent this air movement from washing over or through the attic insulation, which reduces its effectiveness a lot.

Step-by-step process for insulating and airsealing an attic

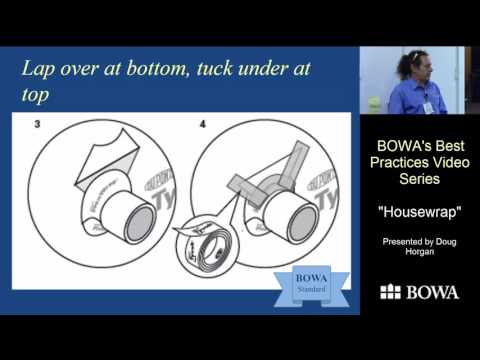

The plan is to create a stable barrier that provides a 1 or 2-inch path over the insulation and also seals the end of the attic insulation where it rests on the top plate of the wall.

First, cut a piece of rigid foam to the right width, which can vary from bay to bay especially in older houses. The ‘right width’ is one that is not so loose that it doesn’t stay in place well enough to seal the edges with caulk or foam, or so tight that it can’t be pushed into place. I crosscut these pieces from 4 x 8 sheets so that the parts are 4 ft. long.

The rigid foam also has to be spaced off the roof sheathing. If there is already one of those cheap pink or blue vents installed, BOOM—just leave it there and use it as the spacer.

Sometimes I rip pieces of foam, apply a little adhesive to one edge, and stick the piece of foam to each side of the opening as a stop block for the foam panels.

Next, slide the foam panel between the rafters and push far enough down so that it extends past the exterior wall plate. Measure the height from the outside of the top plate to where the bottom of the foam will be and cut that height off the end of the 4 ft.-long foam panel.

Press this ripped piece (which may be as narrow as 3 inches) tightly into the cavity to close off the space where the insulation meets the outside of the wall.

Next, seal all the gaps. I use expanding foam because the foam readily fills in the more substantial gaps that I often have (Hey, I’m a drywaller, not a furniture maker).

I should mention that to install the new vents, I have to pull the insulation out from the edge about 18 inches. Rather than folding it back later, I cut away the excess insulation and install it in some other area of the attic after I have finished sealing and when I am improving the original installation.

The uninsulated area will be filled with the blown cellulose or fiberglass later. Covering it all with blown insulation does a much better job than just pushing the old insulation back into place in this very critical area of the attic.

An excellent way to quickly see if there is an open path for air along the soffits is to go into the attic during the day and shut off all lights. If you see the light coming in along the rafter/exterior wall intersection, then there is an open path. Very little light could mean that insulation is blocking the way, there are not enough vents in the soffit material, or both.

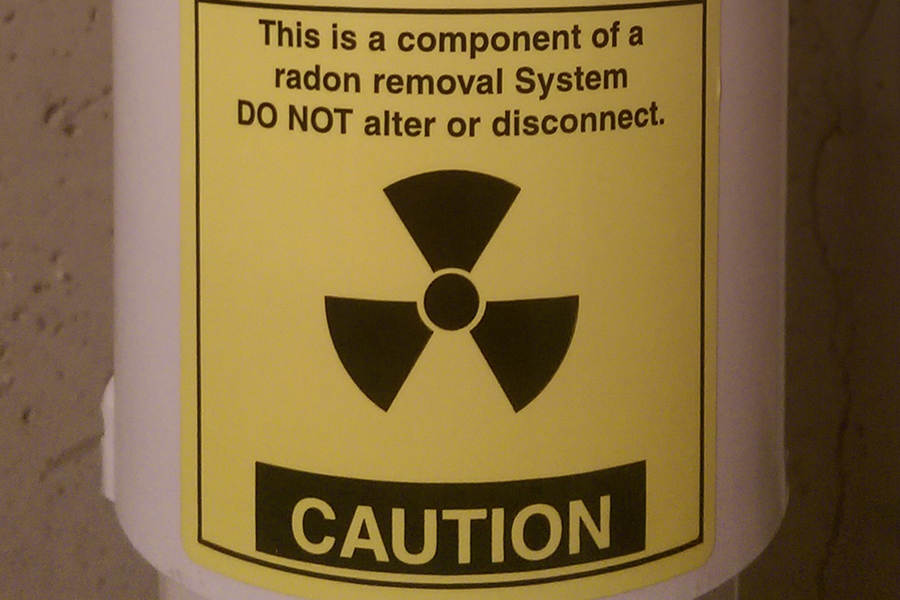

Combustion appliances and tighter buildings can be trouble

Retrofitting an existing house with attic Insulation and other energy efficiency improvements can significantly reduce the natural exchange of air with the outdoors. Whole-house ventilation may be required to maintain acceptable indoor air quality. Mechanical ventilation, like an HRV or ERV, is a good step along the path of continual improvement.

Combustion equipment, on the other hand, is a big red flag. We won’t do any work if unvented combustion appliances are present. Sealed combustion appliances are not a problem as long as they are, indeed, sealed from combustion. Atmospherically vented combustion appliances are a non-starter.

After all the work is completed, I test the combustible appliances to make sure they are drafting properly and test the combustible appliance zone to make sure there is enough combustible air in the zone.

The process described above adds R-value, prevents wind washing, improves airflow, creates a dam to blow insulation against, and improves the performance of the insulation along the attic edge.

I believe all these benefits make the struggle #WorthIt.

After the ventilation, air sealing, and insulation work are done, the clients will save money on their energy bills, but that’s not how I sell it.

What I sell is significantly reduced ice dam problems, and no more moisture stains on ceilings, or moldy attics.