This episode features Jonathan Smegal, M.A. SC a Senior Project Manager with RDH Building Science Laboratories breaking down the topic of air barriers in walls and roofs.

What it is:

air bar·ri·er | er berēər — n (noun)

"A layer in the enclosure that stops the air movement from the interior to the exterior, and it often requires many components that are put together to make a durable continuous air barrier system."

—Jonathan Smegal, RDH Building Science Laboratories

In a nutshell, this is exactly why the concept of an air barrier is so foggy among trade contractors. A lot of people talk about it as if it were a single thing, like a breaker panel or a driveway. In fact, it is a system of parts and connections working together to get a job done.

How it works:

To design it, though, you need to define which layer is the control layer.

"The air control layer is the layer in the enclosure that is responsible for stopping the infiltration or exfiltration of air through the enclosure."

But that critical layer must attach to other layers in other assemblies.

"In most construction it is not a single material responsible for stopping all of the air flow all by itself, is a system of materials often referred to as an air barrier system."

Because the walls connect to the floor and to the roof. And the floor connects to the foundation. And then windows and doors are punched into the walls, so all of the layers must be accounted for.

An air barrier system has some general requirements.

"The primary requirement for an air barrier is that it must be continuous."

It has to actually cover the whole building, and it cannot have a lot of holes in it or it would be more like a screen.

"Ideally, the air barrier material should be strong or stiff to be able to handle most of the pressure drop across the enclosure. The pressures can be a result of the wind, mechanical pressure, stack effect and changes in pressure positive to negative."

Stiff materials are easier to connect together, and weak things break.

"Air barriers also need to be durable, obviously."

So that it lasts at least as long as the rest of the assembly that it is a part of.

"It also needs to be air impermeable."

It must stop air.

You can’t just open the box at the lumber yard and try to blow through stuff. Jonathan says you could suffocate on stuff that won’t pass as an air barrier test.

so,

"You should always check the specifications of any material you plan to use as an air barrier material ..."

Because

"... not every similar material may meet the air barrier requirement."

Why it matters:

It is not a case of tomato tomahto, but it could be a case of whether or not your walls will rot

"It's important to remember that air movement through the cavity brings with it moisture and a lot more moisture than if the water vapor were to slowly diffuse through the layers of the enclosure."

We talked about this in an earlier show about vapor permeance, and we think it's worth repeating.

"Moving air transports significantly more moisture than vapor diffusion."

we think it's worth repeating.

"Moving air transports significantly more moisture than vapor diffusion."

Orders of magnitude more.

"Moving air transports significantly more moisture than vapor diffusion.

A couple other reasons to control air movement through the enclosure are energy penalties and comfort issues."

Hot and cold air leaks cause uncomfortable drafts that you actually have to pay extra for.

As a segway into air barrier materials, let’s tidy up the vapor discussion.

"There's often some confusion about vapor barriers, air barriers and whether or not you need one or both.

I will quickly say that you do not always need a vapor barrier in construction depending on the assembly and the climate zone.

In many cold climates, Canada included, a polyethylene vapor barrier is used as the air control layer and this requires signature effort into the detailing to make sure it is airtight."

So plastic vapor barriers are only used in part of North America ...

"However, air barriers are always a good idea and every climate zone."

Air barrier systems are needed everywhere.

How to do it right:

And they are made with many different materials that have the characteristics of being continuous, strong or stiff, durable, and air impermeable.

"One of the oldest most common types of air barrier materials is probably the sheet applied membrane like Tyvek, or Typar, or Weathermate Plus or countless others by many different manufacturers.

These were developed to replace and improve the air tightness of the building paper that was initially used to slow down the air coming through the enclosure."

The old school stuff was felt paper and rosin paper.

"These sheet membranes require taping at all the joints and sealing to all the penetrations to be continuous."

They also need to be attached to a rigid material, like wall sheathing, at specific intervals, determined by the manufacturer.

"These days there are fluid-applied materials and self-adhered materials that become very strong and rigid when they are applied to the sheathing."

Some paint-on membranes are used for window and door flashings, others as paint-on house wraps.

One of the easiest things you can do is tape the seams in the wall sheathing with high-quality flashing tape. Even if you are adding house wrap or layers of rigid insulation over it.

"In some cases, structural wood sheathing itself or continuous board foam insulation are installed and all the joints are taped as the air control layer."

One other material that is an air barrier is spray foam, which comes in a huge variety of permeabilities to vapor, but is a solid barrier to air movement.

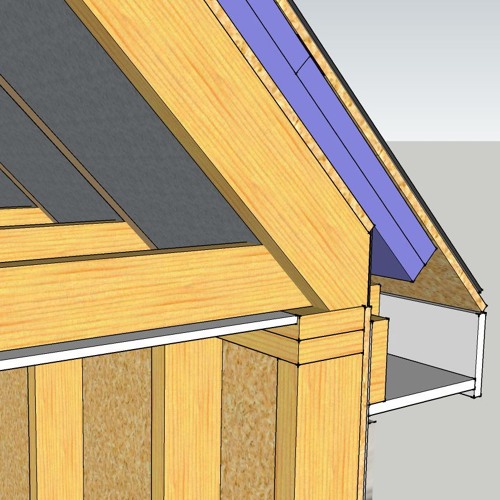

"The important thing to remember about all of these systems is that they can't be the air barrier without additional components and transitions between different parts of the building."

They all need to work together to achieve a common goal.

"Making sure all the parts on all the components of the building are continuously attached together."

Testing for air tightness

To test a house for plumbing for leaks, you just look for the water. To test a house for air leaks, you can’t just look for the air. Because air is invisible.

But if air is under pressure, then you can measure how much is flowing. That’s what blower door tests are for.

"For detached houses it is usually very straightforward, you put a blower door in one of the exterior doors, follow the steps of a standard including opening all interior doors and you determine an air leakage value.

Larger commercial buildings can be much more challenging to test because of the much larger volumes of space inside them, larger mechanical systems of penetrations and oftentimes much leakier overhead doors.

This will usually require multiple blower doors and in some cases the mechanical system of the building can be used to help pressurize the building.

It should not be a surprise that big buildings are harder to test for air tightness than little buildings. They are also harder to make air tight, but one thing they have in common is that the easiest time to make the building airtight is before the interior and exterior finishes go up

"When you can see the air barrier system and the structure and you're still able to actually fix the problem."

Fix the cheap stuff before you install the expensive stuff.

"When we design enclosures, we like to make both sides of the enclosure as airtight as reasonably possible keeping in mind that there should only be one air barrier specified in the enclosure for clarity during design and construction.

Other layers may be referred to as a ‘wind washing barrier’ or ‘convective barrier’ but these are designed to take much less air pressure.

So it is OK to wear a belt and suspenders as long as you label them as such and point out which one is the primary strategy for the prevention of plumber butt.

Speaking of plumber butt, remember—you get paid for what you do and what you know. One thing you can do to know more is to subscribe to this podcast.

Subscribe: iTunes | Google Play | SoundCloud

—7 Minutes of BS is a production of the SGC Horizon Media Network. We’d like to thank RDH Building Science for lending engineers to the show.