Stretchy gasket tape, flanged workboxes, and sealant can solve a HOLE lotta air leaks

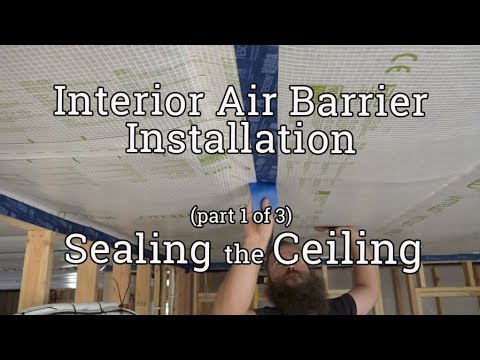

Last time the guys were grooving on a beat and stapling an air barrier. They also taped the sheets tightly.

Now, Ben’s going to cut holes in them just to prove he can seal them tight using two methods.

The first method involves using stretchy tape with split-release paper on the back. Ben removes one half of the release paper and sticks the tape to the outer ring of the work box.

Next, he removes the other strip of paper and bends the tape around the work box and onto the ceiling membrane.

Finally, he forms the tape onto the face of the box.

This also works for penetrations through the walls, like this pile of wire.

Peel one side of the backing tape and stick the tape to the wire, all the way around. Then, remove the rest of the backing paper and stick the tape to the wall membrane. This method also works on bigger masses of pipe and wire.

The other way to do it is to bed the ceiling sheet into the sealant. This means using an airtight work box with a flange built into the perimeter. These come from Allied Moulding.

Poke the nozzle into the hole and above the membrane. Run a continuous bead around the perimeter of the work box and then use a putty knife to bed the membrane into the sealant.

For good measure, Ben runs another bead around the edge of the hole and tools that in place too.

When he has sealed all of the holes in the ceiling, he goes about cutting holes in the walls. These walls also have flanged workboxes, so the same sealant trick works here.

He runs a bead around the flange and tools the membrane into the sealant for an airtight electrical box!

This is the second part of a three-part series on installing interior air barrier/vapor retarder membranes. Also see part 1, Ceilings and part 2, Walls.