Like most of us, Mattias has a lot of random fasteners in jars and cans in a drawer somewhere.

Unlike many of us, he has chosen to do something about it. Small boxes with—wait for it—box joints are made from hardwood drawers that are no longer drawers anymore.

First he rips and resaws the drawer parts in half, so that each drawer piece yields four little box pieces.

Next, he squares off the ends and culls through the pile for rejects.

Cutting them to length on a crosscut sled yields all of the parts for all of the boxes.

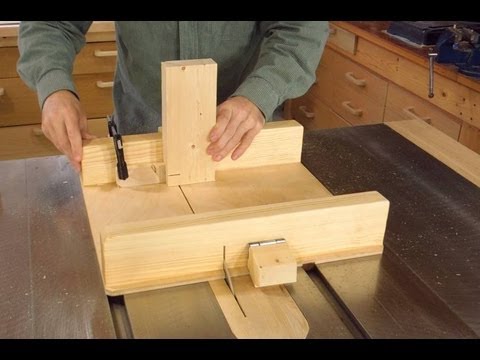

Cutting box joints in tine boxes like this would be a crazy amount of work if he didn't have a box joint jig.

It is at this point that viewers realize that they are being duped. This box-making process is impossible unless we spend another couple of days in our shop making the jig.

With all of the box joints cut, it is glue-up time. Mattias finds that its better to spread the glue across the face of the joints rather than dipping the ends.

The joints are tight enough to not need clamping.

He flush-cuts the box joint ends using a crosscut sled and some spacers, then he cuts the bottoms from thin scraps of plywood.

The bottom is glued directly to the bottom of the box sides and set to dry. The bottoms are cut larger than the box to make assemble faster, then he flush cuts the bottoms with a 30-degree bevel to ease the edges.

A couple of coats of varnish on 'em, and they off to work.

—You can find Matthias Wandel's videos and articles on woodworking—and more mouse experiments—at his website and on his YouTube channel.