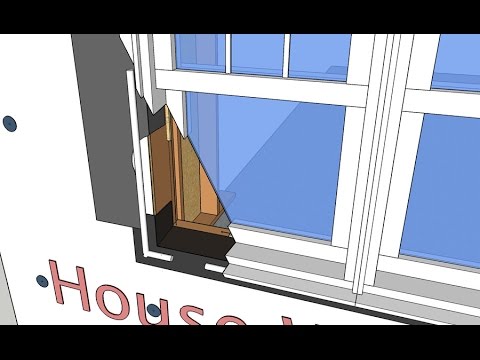

Most remodelers spend a lot of time and effort sloping window sills and flashing the heck out of the opening because, as the saying goes: “There are two kinds of windows, those that leak and those that do not leak yet.” The most common reason for water leaks in windows is faulty installation, so sloping the sill and protecting the framing with flashing tape allows some leakage and an escape route.

As long as the bottom of the window is not sealed to the wall.

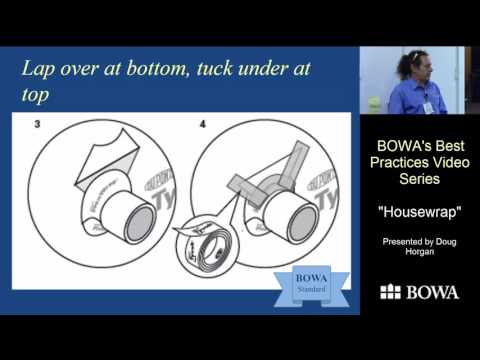

The standard practice is to tape the top and side flanges but to leave the bottom untaped to allow drainage. The air seal is made inside using low-expansion canned foam. Even if you skip the flashing tape over the bottom flange, the flange is sitting tight to the wall, which makes it difficult for the water to escape.

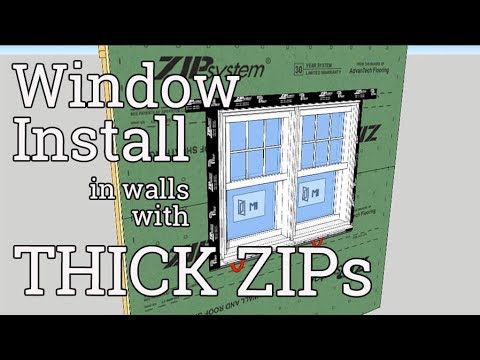

In order to make it a little easier for nefarious water to get out, Ben taps a couple of horseshoe-shaped tile shims between the flange and wall sheathing. The shims come from Russo and are available in multiple thicknesses.

These shims are 1/16 inch thick. Ben saw the detail in the best practice guide of Hammer and Hand, a custom builder in Portland, Ore., and Seattle, WA, and decided to roll it into his standard procedure.