Scouting photos for an upcoming video shoot covering moment frame, walls, foundation, and rim joists.

EDITOR'S NOTE: This is the kind of email that construction editors love to get.

Especially when it comes from a pro.

Hi Dan,

Here's a quick note about the seismic retrofit jobsite:

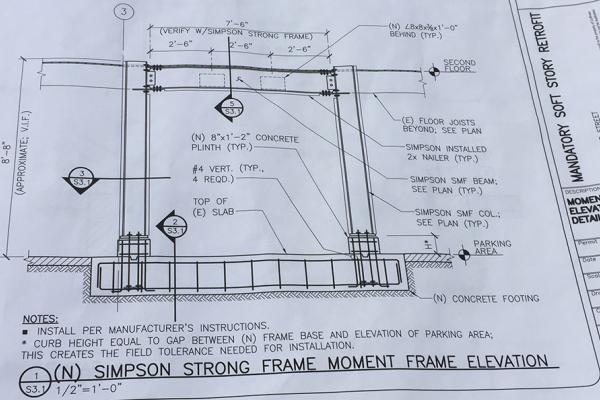

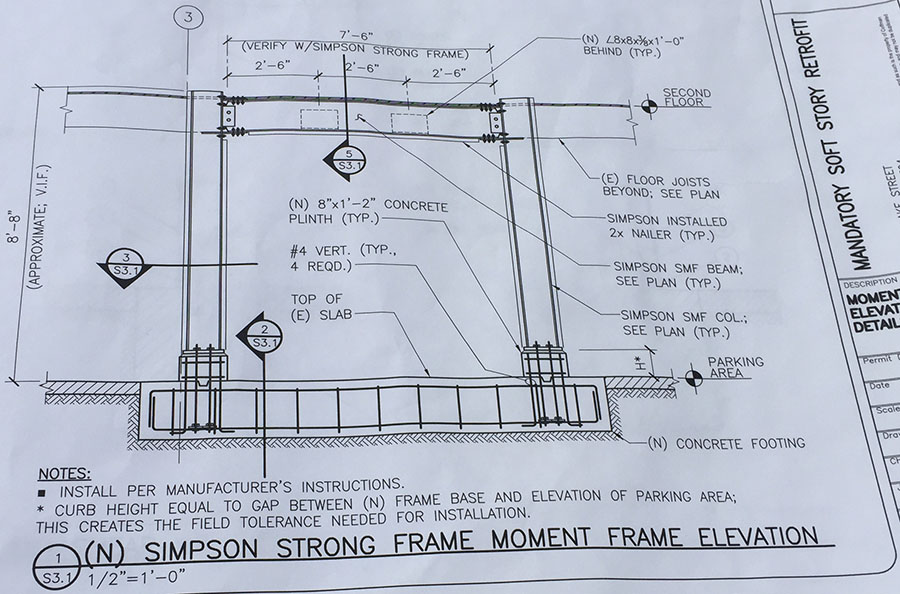

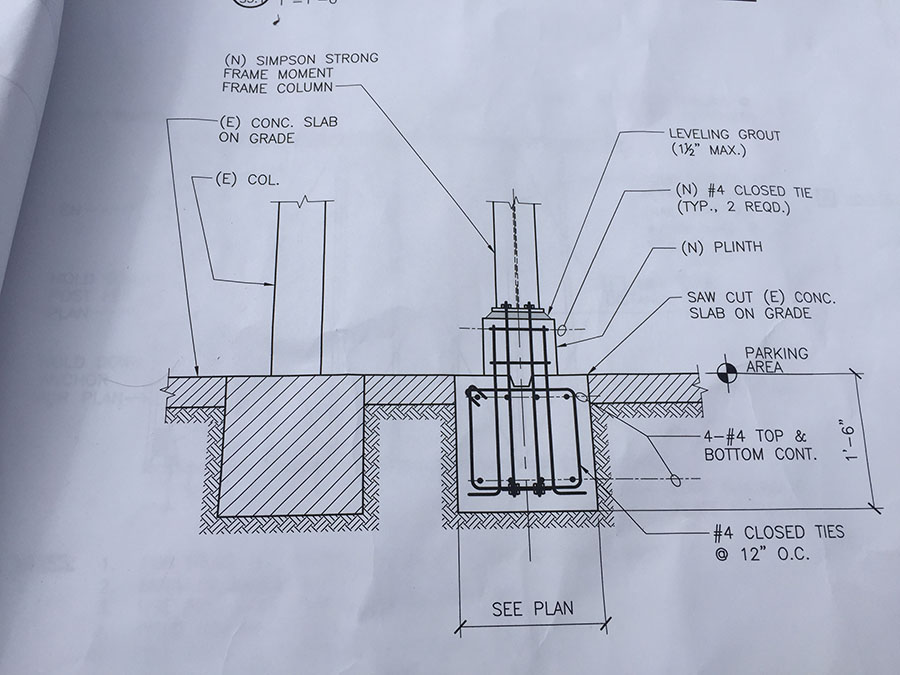

There’s a lot more to this project than the moment frame we talked about, but I'll start there. This apartment building in Berkeley, CA is "soft story" construction because the posts that support the front of it (over the parking area) are not braced. The work's being done as part of a mandatory soft story retrofit program implemented by counties across the state. Without a retrofit the first floor of a building such as this would likely collapse in a major earthquake.

The moment frame will be installed on the face of the center bay and will remain exposed—after being coated with cementitious material for fire code. The owner chose not to box in the moment frame because she does not want to spend anything extra on what will already be an expensive project. Supposedly, there’s a nearby building with the same detail, I'll see if I can grab some photos.

The moment frame will come in pieces next week. The contractor's crew will assemble it and then hang it (lift with a Lull or Bobcat) from a pair of brackets bolted to the header behind it.

The moment frame will later be welded (with an inspector there) to the brackets.

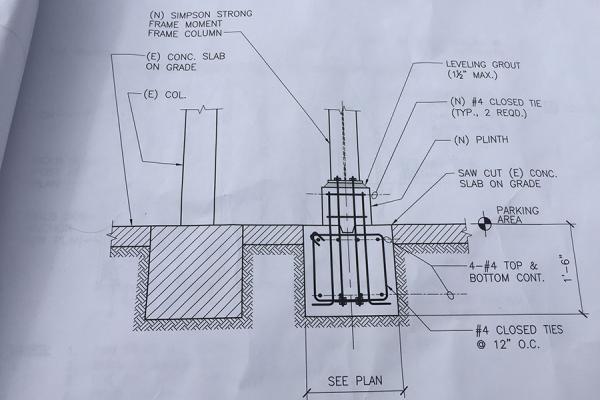

The footing and and piers on which the frame stands will be formed in advance with rebar and tie-downs installed. Concrete will be placed after the moment frame is in position—though not all the way up to the bottom of it.

They will leave a gap and pack it with grout later. The grouted gap is required by Simpson--presumably because that's how the system was tested.

Shear panels and hold-downs tie the walls to the foundation

They’ve broken out stucco on either side of the first floor windows and doors (along the sides of the building) and will be installing hold-downs and shear panels (plywood sheathing plate to plate with specified tight nailing pattern). The hold-downs will be fastened to double studs and bolted to threaded rod anchored (glued) into holes in the foundation.

They'll do something similar at an odd-shaped area at back left corner of building (a few more parking spaces there):

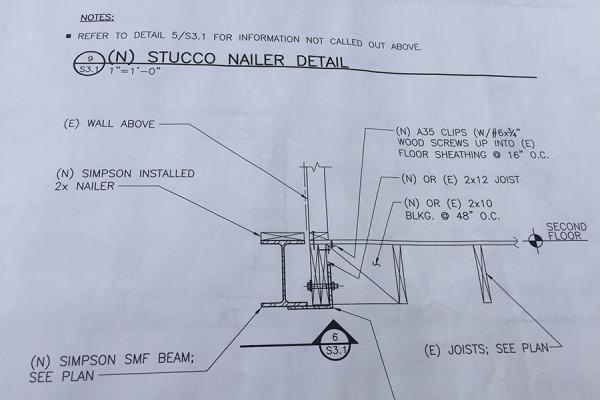

More hardware ties the floor to the walls

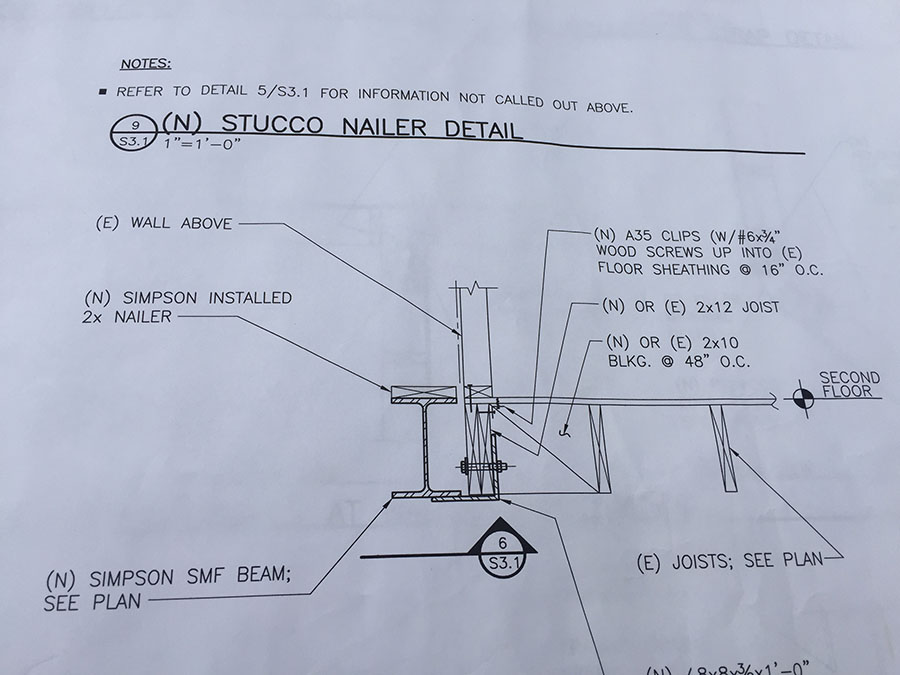

They've removed some stucco along the back of building and will install a lateral force collector (aka "collector") all the way across the rim joist and then clip the rim joist with multiple pieces of hardware to the double plate below.

Part of the underside (ceiling) of that area will be cut out so they can install some kind of collector along blocks attached to the joists above. This and some other details devised by the engineer will allow them to dispense with a moment frame at that location—which costs $7,500+ and is labor intensive to install.

Let me know if you would like to go forward. I figure on being there when the frame is delivered—to see it assembled and installed. Not sure it’s necessary to be there for concrete but I might want to see the grouting and maybe the welding too (sparks and all).

And then a finished shot when the project is done. The contractor, Dennis Cameron, has been doing this kind of work since the '80s and is a trove of information.

Best,

DF

Editor's Reply:

Dear Dave,

YES, please!

Thank you,

Dan

—David Frane is a freelance editor and a good buddy of ours. Formerly, he was editor of Tools of the Trade magazine and website. He lives in Northern California.