How to bend common window profiles on a Tapco brake

J-channel is used at the sides of windows, and an L-shaped head flashing is used at the top. Here's how to form them in the field.

J-channel is used at the sides of windows, and an L-shaped head flashing is used at the top. Here's how to form them in the field.

Step 1: Cut the coil stock to width

J-channel uses 3-1/2 inches of coil stock. The coil stick cutter slices a line 1-1/2 inches past the clamp, so set the coil stock with 5 inches protruding past the clamp and cut.

Step 2: Hem the edge

Hemming the edge reduces the chances of slicing your hands on the sharp metal and it also produces a stiffer, more attractive edge.

- Insert the coil stock 1/2 inch into the clamp and clamp.

- Bend as far as the brake will allow, using both handles to ensure a consistent bend.

- Reclamp the brake and drop the edge into the front of the brake using the hinge to continue the fold creating the hem.

Step 3: Complete the J-channel

- Reinsert the workpiece into the clamp 3/4-inch with the finish side down.

- Bend 90 degrees and release the clamp.

- Slide the coil stock out an additional 3/4-inch

- Bend 90 degrees again to complete the J-channel

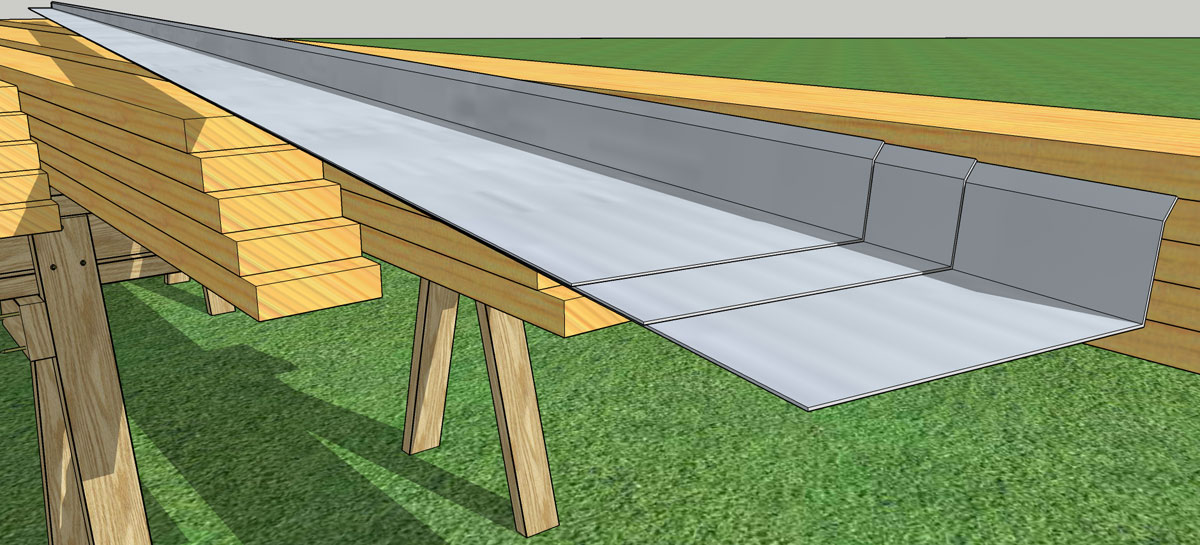

Bend an L-shaped window head flashing

- Hem the edge

- Insert the hem into the brake, finish side down, and clamp the brake at the edge of the hem.

- Bend 90 degrees and release the clamp.

- Slide the long edge in with the finish side up. Leave enough flashing outside the clamp to cover the window head.

- Bend 90 degrees for a complete window head flashing.