Tight joints

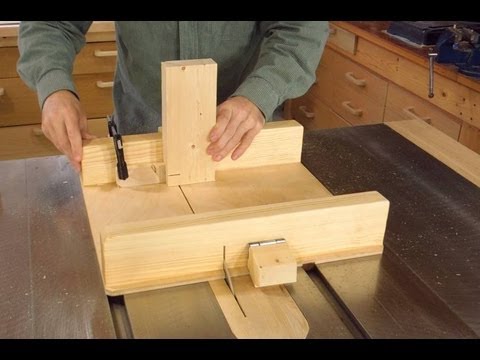

The key to making big gates that will not sag are the half-lap joints. They are big joints with a ton of surface area for glue.

To cut the lap joints:

- Use a dado blade. Paul keeps a dado blade on a portable table saw for such projects.

When using tablesaws, or any saw for that matter, wear safety glasses and a dust mask.

- Cut the lap joints by carefully cutting the inside-most dado, and then hogging out the remainder. If the inside cut is not square, it will be difficult to make the corner square.

- If the boards are slightly different thicknesses, as is often the case with fencing stock, either adjust the depth of dado (for discrepancies greater than a 1/16 inch) or do not sweat it (for discrepancies less than 1/16 inch).

- Glue both surfaces of the joint, and put them together—making sure the inside is tight. Do not worry about the outside, any overlap can be trimmed.

- Screw the joints.

- Set a cross brace diagonally across the frame. Lay the brace under the frame and line it up in the corners. Block under the other two corners keeps the frame flat.

- Align the cross brace with each corner and mark the angle with a pencil.

- Because this gate is a rectangle and not a square, note which corner goes where, or you may get into one of those glue-up discombobulations. Paul writes 'Face in' on the face of the cross brace.

- Additional blocks under the corners act as stops for keeping the brace flush when it is set into place.

- Use a pocket hole jig—one of the essential tools needed for woodworking—to drill pilot holes for fastening the brace.

Tool tip from Paul:

"Jorgensen clamps are f—

Fantastic."

So he uses them a lot.

- After the pocket holes are drilled, glue the end grain of the brace and set it into place.

- Screw it.

- Fence boards will cover the screw holes (and the 'face in' writing).

Setting the gate in place: how to brace a wide gate

- Clamp a fence board on either side of the opening.

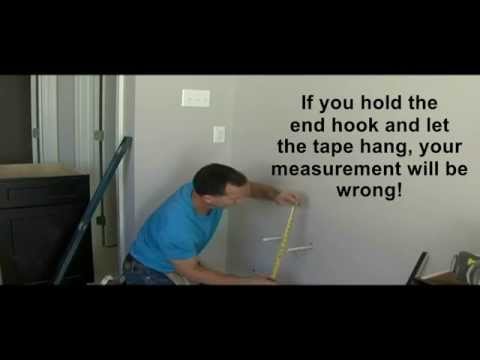

- Run a string from one to the other and check the level. Paul is confident that one board will need to be cut because the ground is not flat.

- Set the board that will need to be cut upside down, butting the top to the ground. This way you can mark the cut rather than transferring the mark. You can also use a laser level or builders transit.

- Measure down to the level line—3-1/2 inches in this case—and cut the bottom of the board.

- Block the back of the post so the hinge screws will have something more to bite into than just fence boards.

- With the bottoms cut, install the first fence board to the frame and fasten in place with the hinges.

If you mess up a little bit and need to move the hinge up, use golf tees to plug the old screw holes. Now you can run a screw next to the old one and it will bite.

With both ends set, fill the field of the gate sections with fence boards. To make this easier, screw the two gates together temporarily with a block of wood.

—Paul Ricalde is a home improvement contractor and fireman in New Orleans, LA. His YouTube channel is rich with construction/remodeling videos.