Tightening an old house or building a tight new one means that you can't leave ventilation to random leaks anymore. You have to control it.

[Ed's note: This article is reprinted with permission from the Home Innovation Labs. It is based on one of their Tech Notes, and it is lightly edited]

Whole-house mechanical ventilation is the intentional exchange of indoor air with fresh outdoor air at a controlled rate using fans.

The purpose of whole-house mechanical ventilation is to improve indoor air quality. Historically, mechanical ventilation was limited to local-exhaust (kitchen and bath exhaust fans) for spot control of moisture and odors. Houses commonly had enough natural ventilation, through leaky building enclosures, that whole-house mechanical ventilation was not necessary.

Houses have become significantly tighter during the past 15-20 years as a result of changing codes, energy efficiency programs, and an overall desire to reduce energy use. Above-code programs and more recently the building codes have generally made controlled whole-house mechanical ventilation a requirement.

Benefits of whole-house mechanical ventilation

- A consistent supply of outdoor air for improved indoor air quality and occupant comfort

- Control over the amount and source of outdoor air

- Dilutes indoor contaminants, such as formaldehyde, cleaning agents, odors, and allergens, which now take longer to dissipate in a tighter house

- Helps control relative humidity and reduce moisture accumulation during the heating or temperate seasons

- Meets new 2012 IRC building code and many energy and green program requirements

Types of whole-house mechanical ventilation

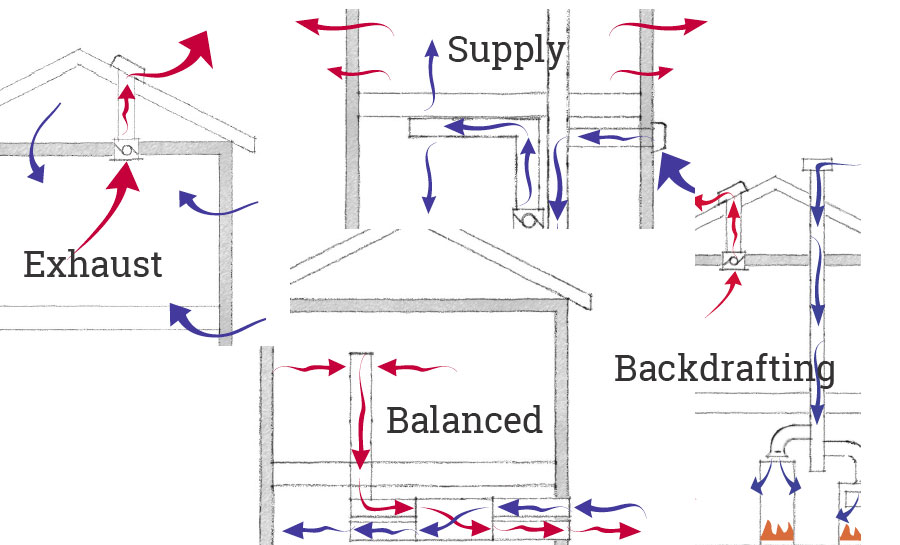

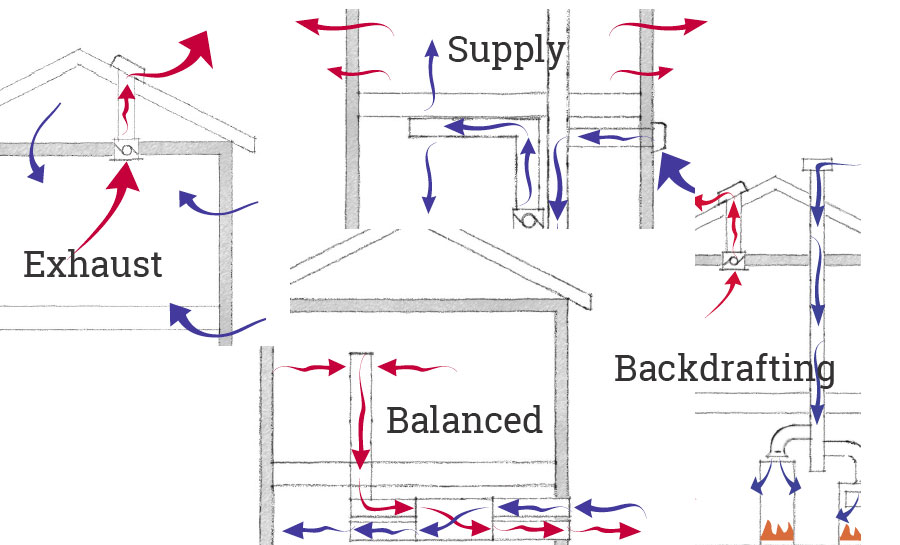

There are three types of whole-house mechanical ventilation systems: exhaust-only, supply-only, and balanced. Each system uses a combination of fans, ducting, dampers, and controls; and they each have different pros. cons, and costs associated with them.

Exhaust-only tends to depressurize the building

Exhaust-only tends to depressurize the building

Exhaust-only ventilation tends to consist of a fan, commonly an efficient bath fan, exhausting indoor air. Outdoor makeup air is drawn into the house through leaks in the building enclosure.

Pros/cons/cost:

- Contaminants may be drawn into the house from an attic, garage, crawlspace, or wall cavity

- Potential to draw moist outdoor air into the wall cavity that could condense during the cooling season and cause moisture problems, particularly in warm humid climates.

- Outdoor air may not be well distributed

- Could cause or contribute to back-drafting of combustion appliances

- Lowest installed cost and low operating cost

Supply-only tends to pressurize the building

Supply-only tends to pressurize the building

Supply-only ventilation is usually a fan drawing outdoor air into the house. Indoor air escapes through the building enclosure and exhaust fan ducts.

Supply-only could be a dedicated system, or more commonly a central-fan integrated (CFI) system.

With a CFI system, outdoor air is ducted to the return plenum of an HVAC air handler that draws in and distributes the outdoor air.

Pros/cons/cost:

- Minimizes contaminants entering through the building enclosure

- Potential to drive moist indoor air into the wall cavity that could condense and cause moisture problems during the heating season in colder climates.

- Outdoor air is drawn from a single, known location for best air quality

- Must be designed to avoid occupant discomfort due to cold outdoor air.

- For a central fan integrated (CFI) system, air is well distributed and can be filtered and conditioned.

- Low installed cost, however for a CFI system, the electronically commutated motor may increase the initial cost, and operating cost may be higher

A combination of supply-only and exhaust-only components could be a practical and cost-effective alternative to an HRV or ERV.

Balanced limits pressure imbalances

Balanced limits pressure imbalances

Balanced ventilation systems are a combination of exhaust and supply methods providing approximately equal indoor exhaust and outdoor supply air flows (e.g. an exhaust fan combined with a supply fan or passive inlet vents).

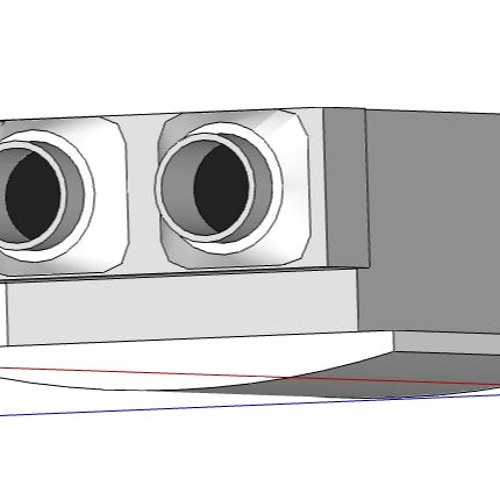

A balanced system may include a heat recovery ventilator (HRV) or an energy recovery ventilator (ERV).

Pros/cons/cost:

- An HRV transfers a portion of the heat between the exhaust air and the fresh air; an ERV transfers heat and moisture.

- An HRV or ERV may be ducted independently or integrated with the heating and cooling duct system.

- An HRV or ERV provides the benefits but limits the drawbacks, of supply-only and exhaust-only methods.

- Generally, an HRV is recommended for dry, cold climates, and an ERV is recommended for moist, warm climates.

- Highest installed cost for HRV or ERV due to equipment and additional ducting. Energy transfer operating cost savings is somewhat offset by fan energy, particularly when integrated with the HVAC system, and additional maintenance.

What air flow rate is required?

ASHRAE Standard 62.2-2010 is a ventilation standard for new and existing homes, and is the basis for the whole-house mechanical ventilation rates in the 2012 IECC and 2012 IRC.

Minimum continuous and intermittent rates are prescribed using tables.

The recently released ASHRAE 62.2-2013 prescribes a higher minimum continuous rate that can be modified based on building tightness test results.

Actual air flow doesn't always match what's written on the box

Measured air flows are frequently less than design values due to an overly restrictive duct system. An efficient duct layout will reduce air flow resistance and help ensure expected performance:

- Locate termination hoods to minimize duct lengths and number of elbows.

- Account for pressure drop of all components including termination hoods.

- Use manufacturer’s air flow and static pressure data; prescriptive duct sizing tables may use different static pressures.

- Increase duct diameter if necessary.

- Install in accordance with manufacturer’s instructions.

Controls that prevent under-ventilation and over-ventilation could reduce excessive energy use (heating, cooling, and fan) or occupant discomfort. A control may be a timer, humidistat, or other duty-cycling device that controls ventilation based on time, cumulative hourly run-time of the HVAC system, or severe outdoor conditions.

Backdrafting can pull poison into a house

Backdrafting is a dangerous condition when negative house pressure is sufficiently high to draw products of combustion from fuel-burning appliances into the house (instead of being vented out of the appliance through a chimney or vent).

Back-drafting can potentially lead to unsafe levels of carbon monoxide — an odorless and colorless poisonous gas that can cause sickness or death. Combustion appliances with potential for back-drafting include furnaces, water heaters, fireplaces, or other equipment that burns natural gas, propane, oil, kerosene, or wood.

The factors that affect pressure conditions inside a house include stack effects, wind effects, HVAC, and exhaust fans.

Exhaust fans can create a negative pressure inside buildings leading to back-drafting

A bath exhaust fan used for whole-house mechanical ventilation and operating at the code prescribed continuous rate (e.g., 50-80 CFM) could cause back-drafting, but the operation of a larger capacity exhaust fan (e.g., a 300-1200 CFM kitchen range hood fan or a 150-400 CFM in-line multi-inlet bath fan) is more likely to cause back-drafting unless makeup air is provided.

Other exhaust appliances (clothes dryer, central vacuum, and conventional bath fans) operating concurrently would further increase the potential for back-drafting.

Combustion appliances can be tested for potential back-drafting.

The BPI Building Analyst Professional Standard (BPI 2012) includes a procedure, summarized below, to perform a depressurization test for each combustion appliance zone (CAZ):

- Measure a baseline pressure

- Measure the largest negative pressure, based on the combined effects of exhaust appliance operation, air handler operation, and door position

- The difference is the worst-case depressurization

- Compare to the back-drafting depressurization limit for the appliance

This procedure is generally performed in conjunction with testing for building tightness, carbon monoxide, and spillage and draft for natural draft and mechanical draft furnaces and water heaters.

Based on test results, action items are identified to maintain combustion safety.

Tightening an old house can cause problems

Retrofitting an existing house with energy efficiency improvements could significantly reduce the natural air exchange rate with the outdoors, potentially creating a back-drafting hazard. Whole-house mechanical ventilation now may be required to maintain acceptable indoor air quality.

Combustion safety testing could be used to identify existing issues before retrofit work begins, and to confirm the safe operation of combustion appliances after work is complete.

Combustion safety and exhaust fan operation should be considered together. Generally, the tighter the house, the more likely it is that depressurization could be a problem, even when code approved combustion air requirements are met. A worst-case depressurization test will help to determine if non-direct vent combustion appliances will backdraft.

Suggestions to prevent back-drafting and other combustion safety hazards:

- Ideally, install direct vent (outdoor air for combustion) equipment.

- If direct vent equipment is not feasible, install induced draft or power vented combustion appliances.

- Exhaust-only whole-house mechanical ventilation may not be appropriate where natural draft and induced draft appliances are installed.

- Confirm that combustion appliances including fireplaces are installed and commissioned in accordance with code and manufacturer instructions.

- Perform worst case depressurization testing, as required, in accordance with industry standards, such as from the Building Performance Institute (BPI 2012), Air Conditioning Contractors of America (ACCA 2011), The Energy Conservatory (TEC 2012), or other approved tests.

Suggestions for best performance of whole-house mechanical ventilation systems:

- Determine the required minimum continuous air flow rate [Table M1507.3.3(1), IRC].

- Select the most appropriate type of system based on desired performance factors.

- Select equipment fan size based on the intermittent operation as required [Table M1507.3.3(2), IRC].

- Select controls to avoid under-ventilation and over-ventilation.

- Design duct layouts to ensure that tested air flow rates will meet design requirements (using manufacturer instructions and industry standards such as Manual D (ACAA 2009)).

- Inspect bath and kitchen exhaust systems for proper installation — these are the most effective ways to control moisture.

- Test the operation of all mechanical ventilation systems and confirm that controls are operating properly.

Code references for 2012 IRC

Chapter 3 Building Planning

- R303.4 Mechanical ventilation requires whole-house mechanical ventilation in accordance with M1507.3, where the tested air infiltration rate is less than 5 ACH50 in accordance with N1102.4.1.2.

- R303.5 specifies location of intake and exhaust openings, and R303.6 specifies protection required for openings that terminate outside.

Chapter 11 Energy Efficiency

- N1101.3 (R101.4.3) additions, alterations, renovations or repairs defines compliance requirements for altered and unaltered portions of an existing building and additions.

- N1102.4.1.2 (R402.4.1.2) Testing requires a tested air leakage rate not exceeding 5 ACH50 in Climate Zones 1-2, and not exceeding 3 ACH50 in Climate Zones 3-8 (see N1101.10 (R301.1) Climate Zones).

- N1103.5 (R403.5) Mechanical ventilation (Mandatory) requires mechanical ventilation in accordance with Section M1507 or other approved means, with fan efficiency that meets the requirements of Table N1103.5.1, and requires that outdoor intakes and exhausts have automatic or gravity dampers that close when the ventilation system is off.

Chapter 15 Exhaust Systems

- M1501.1 Outdoor discharge requires mechanical ventilation exhaust to be discharged outdoors in accordance with M1506.2, which provides distance requirements for location of exhaust openings. Outdoor discharge is also required in M1507.2 Recirculation of air.

- For requirements concerning kitchen exhaust rates, see M1503.3; for makeup air requirements for kitchen range hood exhaust rates exceeding 400 cfm, see M1503.4.

- M1507 Mechanical Ventilation prescribes minimum airflow rates for continuous—Table M1507.3.3(1)—and intermittent—Table M1507.3.3 (2)—whole-house mechanical ventilation systems, and local exhaust rates for kitchens and bathrooms—Table M1507.4.

Chapter 16 Duct Systems

- For requirements for duct design, construction, and installation (see also M1506 Exhaust Ducts and Exhaust Openings).

Chapter 17 Combustion Air

- for requirements concerning solid-fuel burning and oil-fired appliance.

Chapter 24 Fuel Gas

- for requirements concerning fuel-gas piping systems, appliances, accessories, venting systems, and combustion air.

Additional Sources:

- Kitchen Exhaust Best Practices

- Whole-House Ventilation Systems Technology Fact Sheet. (2002) U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Building Technologies Program, National Renewable Energy Laboratory

- Guide to Home Ventilation (2010) U.S. Department of Energy, Energy Efficiency and Renewable Energy

- Indoor Air Quality / US EPA

- Mechanical Ventilation: Breathe Easy with Fresh Air in the Home (2006) EPA Energy Star Program

- Review of Residential Ventilation Technologies (2005) Russell, M., Sherman, M., and Rudd, A. Lawrence Berkeley National Laboratory

- Ventilation Guide (2011) Rudd, A., Building Science Press, Inc.

- Air Flow Control in Buildings (2009) Straub, J., Building Science Corporation

—This article is reprinted with permission from the Home Innovation Labs, a full-service market research, consulting, product testing, and accredited third-party certification agency dedicated solely to issues related to the home building industry. The original Tech Note is here.