A solid flat surface for building begins with a LOT of aggregate and many passes with a compactor

Hi, I’m Jake with Aarow Building and today we're at our Prairie Modern project. This is a home that we're building in Columbia, Missouri designed by Steve Baczek with Steve Baczek Architects out of Reading Massachusetts.

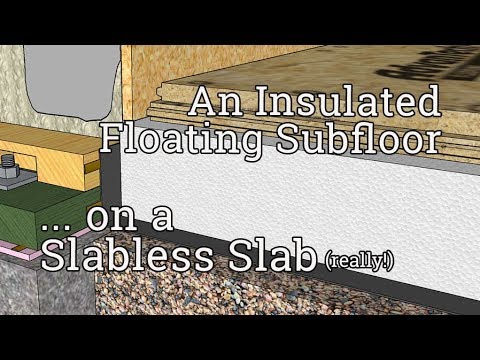

Today we're going to talk about our slabless assembly. This floor assembly is superinsulated, but one of the unique things about it is we did away with the concrete.

So what we have is about ten inches of compacted lime waste aggregate, then a poly vapor barrier—all the seams are taped—and then we have four inches of EPS foam, and then two layers of Advantech subflooring that are glued, screwed, and offset seams and in opposite directions.

Once we get to that top layer of Advantech, and everything is screwed down, it is rock solid.

—Jake Bruton

It all begins with digging a hole

Slab on grade construction works best when the ground is level, so they had to push around a little dirt to even out the humps and divots. Most of the site was pretty level, but there was a swale…

When they had a pretty flat space to work, they dug the footings, which are 32 inches deep in this climate.

Along with the stem walls, they poured a pad for the garage where they stacked the pre-framed components. Plumbing was stubbed out and they packed down the earth inside the foundation walls.

Walls and roof are framed before subfloor is laid

The walls are framed with 2x8 and the mudsill is placed atop sill sealer, which was sealed to the foundation and to the mudsill with an elastomeric caulk.

They left the back wall out in order to make a ramp for the track-driven compactor to level and compact the crushed stone base.

But before they could go further with the slabless slab, they needed to dry in the house, so they turned to framing.

The walls are framed with 2x8s and the walls are placed atop sill sealer which is sealed to the foundation and mudsill with elastomeric caulk. They left the back wall out in order to make a ramp for the track-driven compactor to level and compact the crushed stone base.

They were able to frame all of the window and door frames, along with header assemblies, in the shop which offered a flat, cool concrete floor during the heat of July in Missouri.

When the framing package was ready they loaded it into their trucks and stacked it on the garage slab.

The walls were framed on the compacted base and stood before the window and door frames were installed. They sheathed the walls with ZIP R sheathing, an OSB product with an inch of foam insulation on one side and a painted-on weather barrier on the other.

The roof was framed with trusses and sheathed with regular ZIP sheathing.

The slabless slab and subfloor are next

Now, they add the crushed gravel base, which replaces the slab. The crushed stone was screeded level with a 2x4 like you’d screed a wet slab.

"Once the compacted aggregate has been sufficiently screeded, we will wet the surface one last time, compact one more time, and that gives us a locked-in-place solid, flat surface to build on.

That flat surface, I believe, is closer to dead-flat than I've ever had a concrete slab poured for any home that we've built. I was really happy with that ability to adjust during the process."

At this point, they were ready to do the other cool aspect of this floor—and the reason I flew out there: the floating insulated subfloor assembly.

—This is the first in a series of four videos covering an insulated subfloor over a slabless slab.