This time on 7 Minutes of BS, Jonathan Smegal, M.S., describes his work at RDH Building Science Laboratories testing various wall sheathing materials for air tightness. The results are somewhat surprising but, truthfully, not a deal-breaker for most builders and remodelers.

"We're talking about the air permeance of wood-based structural sheathing in the construction of wood-framed buildings."

What air permeance of structural sheathing is

air per·me·ance | ɛər pur-mee-uhns

A measure of how much air can pass through a material or assembly; specifically air moving between the inside and outside of a building.

—Dan Morrison, editor, ProTradeCraft

Taping the seams of sheathing lowers air leakage

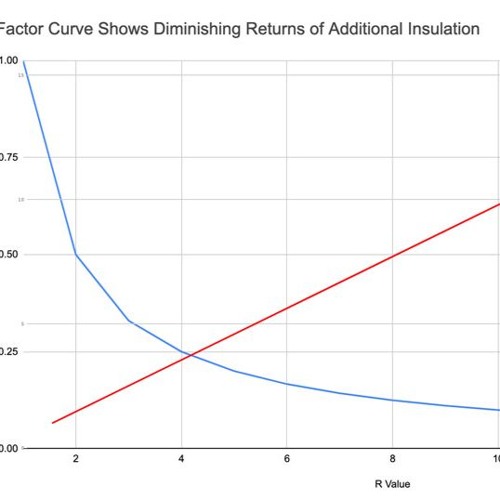

As builders try to hit zero energy targets, air tightness becomes a key focus.

"Air tightness is important in all climate zones regardless of whether it’s a warm climate or a cold climate…"

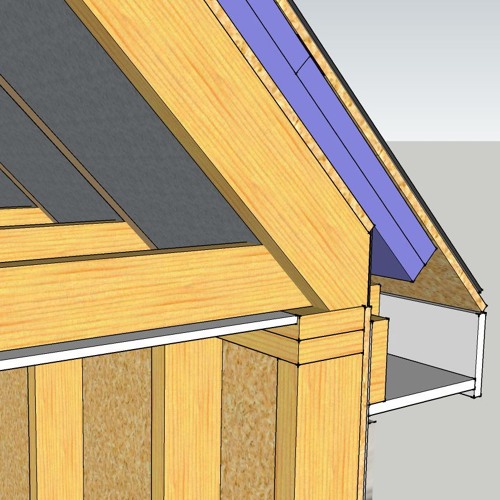

One of the best ways to tighten a structure is to tape the seams of the structural sheathing, whether it is one of the kinds with a built-in WRB or not.

"It is one of the best ways to get a high level or air tightness on the building. There has been many successful tape studies and many examples of buildings that have used a taped-sheathing approach to get high levels of air tightness"

Air leakage is not just an energy bill problem.

"The risks of air leakage differ for different climate zones, but really it comes down to the air that moves through the enclosure is gonna move moisture."

Moist air turns into puddles when it touches a cool surface, like inside the wall cavity.

"So it really comes down to energy consumption and durability related to moisture accumulation and condensation within ght cavity. You can get moisture accumulation in hot humid climates as air moves IN to the building from the exterior and condenses on the drywall or condenses on materials on the interior where its air conditioned."

In cold climates or in the winter, moisture comes from inside the house and condenses on the back of the sheathing.

"…and it results in moisture accumulation, rot, mold, and things like that."

Some Passive House builders discovered permeable OSB

So there’s no controversy there. Taping the seams of the sheathing works as an air barrier. Of course, that assumes that the sheathing is an air barrier.

But is it?

"In about 2015 there were some anecdotal stories from some general contractors on the internet, blog posts, etc. These builders were trying to build passive house construction, and they were having trouble achieving the air-tightness requyired for Passive House, 0.6 ACH…"

The builders thought air was leaking through the OSB panels that they had dutifully taped the seams of.

The builders came up with a jobsite science test and seemed to verify that if you blow hard enough, you can blow right through OSB.

To get the tightness back, one of the projects added an external WRB with the seams taped. The other building already had siding installed, so they flash-coated the inside with spray foam.

"And then, they achieved their passive house air tightness. These anecdotal stories led us to wonder if it was the OSB stopping them from achieving their air tightness."

So they huddled up in their secret BS lab and tested brand-new OSB and Plywood for air tightness.

"So we wanted to see if brand-new products were even meeting the air barrier material requirement.

The air barrier material requirement is in the building code as 0.02 liters of air per second per square meter of surface area at 75 pascals,

or .004 cubic feet per minute per square foot of surface area at about 1.6 psf"

Changing the units doesn't make it easier to visualize.

"The standardized test is ASTM E2178"

Standard Test Method for Determining Air Leakage Rate and Calculation of Air Permeance of Building Materials

"The test essentially takes a 1-meter by 1-meter sample sealed in an apparatus and you apply a pressure difference across the sheathing, and you can measure the air leakage through the sheathing."

If a sheathing scores .02 liters per second, it is an air barrier material.

"One of the challenges is that many North American building codes and standards will claim that you can achieve the air barrier requirement with as little as a ⅜-inch thick piece of OSB or plywood."

And there’s the rub. These high-performance builders were not hitting air-tightness targets even though they were using approved air barrier materials. What about the actual performance of these so-called air barrier materials?

Did they pass the lab test?

An OSB air leakage test in an actual building science lab

"We tested Huber Zip, a composite sheathing product with an integrated air and water barrier in the surface of the material, compared to OSB and Plywood sheathing.

We ended up testing ten new samples combined of the Huber ZIP, OSB, and plywood. What we found is that the three samples of ZIP met the air barrier requirement.

The four samples of OSB—one of which was ⅜-inch and three of which were 7/16-inch did not meet the air barrier requirement.

For the plywood, we tested three different thicknesses. ⅜-inch, ½-inch, and a 15/32-inch, and they all met the air barrier requirement when they were tested brand-new off the shelf.

To increase the realism of these tests, we weathered the materials by soaking them for 24 hours, drying them out, and repeating that for a total of three times.

What we did find is that all of the OSB samples got worse, and there was a change in the plywood air permeance; one didn’t meet the air barrier requirement following that, and there was very minimal change in the Huber Zip samples."

Apparently, the coatings of these panel products do a good job of doing their job.

It is unlikely that the structural sheathing is the weakest link in your air barrier system, but the fact that the published numbers may not be accurate anymore is worth noting.

New large-scale testing is needed to account for new formulations of old products

At the least, to consider whether a large-scale test is in order to bring them up to date with currently-available building products. The last tests were done twenty years ago.

"The original test results were done in 2002. IRC Canada did some testing on small discs, essentially, of OSB and I think that is the only test that these values could come from, twenty years ago.

And I feel like with changes in the industry, changes in materials, changes in available chemistries, stuff like that, that the OSB must have changed, right?

OSB is made from wood strands and adhesive. The wood may be a little bit different, but more likely; the adhesive part is different.

Maybe they’re using less of it, and maybe they’re using a different formulation; either way, the panels are not performing as they used to with regard to air movement.

Some testing in Europe backs these data up, too.

"There was a test in Belgium that was done, and it was done of 10 or 12 samples of 19-milimeter, so almost 3/4 -inch OSB and only one of the samples passed the air barrier requirement.

Thise were all European brands, but it indicates that things have changed from what it was."

Well, it was wood; now it’s wuzwood.

When planning your air barrier system, think "layers" instead of "unicorns."

If you’re going for high performance, like PHIUS certification, you may want to avoid straight-up OSB with taped seams and go for one of those pre-applied WRB sheathings or a fluid-applied membrane.

Don’t forget you get paid for what you do and what you know.

Now you know more about air barrier systems, so go demand a raise. And let me know how that works out for you.

—7 Minutes of BS is a production of the SCH Horizon Media Network.

More building science to explore:

- Air Barriers: 7 Minutes of BS

- Housewrap and Sheathing as an Air Barrier

- Energy Star Checklist, Section 1: Overall Air Barrier and Thermal Alignment

- Dirty Harry Does Insulation (buildingscience.com)

- Continuous Air Barrier in Exterior Walls (Building America Solutions center)