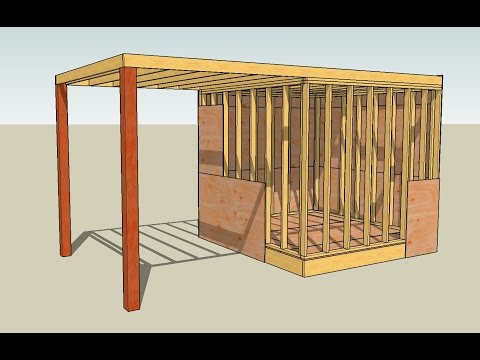

This educational video from the former NAHB Research Center (now called the Home Innovation Labs) outlines general principles and practices for floor framing and subfloor installation.

It covers engineered wood as well as dimensional solid lumber and is a fair starting point for understanding the basic framing concepts.

Material delivery and storage

Protect materials from the weather until you are ready to use them. Elevate panels off the ground using at least 2x scraps, but three inches out of the mud can protect those bottom sheets even better.

Cover the panels with plastic and stake down the edges, or weigh them down with rocks. A best practice is to add a "ridge' to the top of the stack to slope the plastic away from the panels and shed water faster.

Subfloor layout and specification

Install subfloor panels according to local building codes and material properties. The materials must be sufficient to meet or exceed the span, spacing, and loading requirements of the floor.

Framing materials may include:

- I-joists

- 2x dimensional lumber

- Structural composite lumber, such as LVL, PSL, or GluLam

- Subfloor sheathing materials

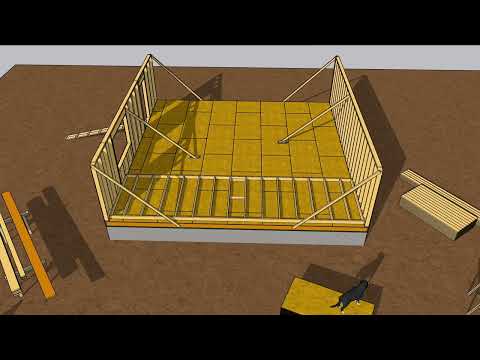

Install floor framing

Take a minute before cutting any wood to determine the joist spacing, locations of structural blocking, any joist hangers needed, and rim joist installation details.

Joist spacing and span are critical to meeting the load and deflection criteria. If joists are incorrectly spaced or undersized, the floor may feel "bouncy" or "spongey."

Blocking can be used to distribute a load or to provide backing for nailing. Structural blocking is typically noted on the plans, but nailer backing is not.

The rim joist transfers lateral and vertical bearing loads and should be installed straight and with solid bearing on the mudsill.

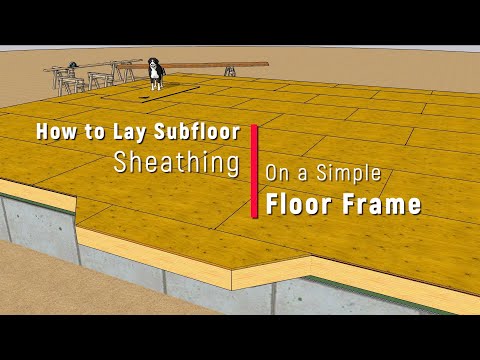

Install floor panels

Make sure the framing is level, clean—or at least free of loose debris—and dry before applying subfloor adhesive and subfloor panels.

The floor panel type depends on the floor covering and underlayment that may be needed. Some panels have underlayment already incorporated into the panels.

Snap a line 48-inches from the rim joist, perpendicular to the joists, and use it as a guide to establishing a straight edge and setting up subsequent rows to be installed straight as well.

Use construction adhesive suitable for exterior subfloor applications and fasten with either ring-shank nails or screws. Applying construction adhesive to the groove of tongue-and-groove panels can help stiffen the subfloor.

Don't apply more than one or two sheets of adhesive, or the glue may be set up before the panel is placed, rendering the adhesive useless.

Dimensional lumber must be crowned with the crown side facing up.

Spacing and fastening subfloor panels

Tongue-and-groove geometry usually provides the proper spacing along the long axis, but to properly space the panels on the ends, use two 8d nails to provide a 1/8-inch space, which will allow for slight expansion.

Don't overdrive nails or screws; drive them flush with the subfloor surface.

Check to make sure the installation is correct in its nail spacing, panel end spacing, and overall quality.

More floor framing and subflooring info to explore: