A few really cool tricks for an otherwise mundane process: sheathing.

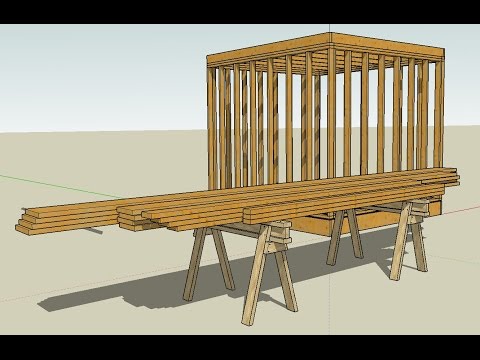

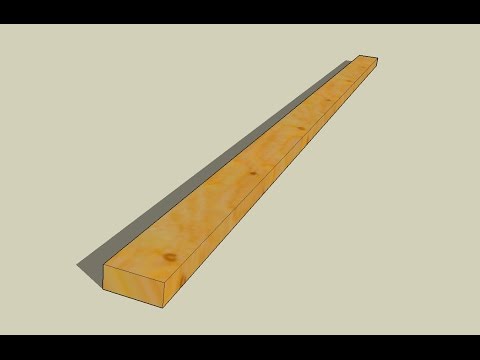

In the first part of this series, Matt showed how to make a 2x4 and how to quickly turn that 2x4 into a four-walled phone booth. In second segment, he showed how to model other nominal framing sizes and assemblies, like walls and floors.

In this part, he makes—and installs—various types of sheathing products: tongue and groove subflooring, OSB wall sheathing, Polyisocyanurate foam panels, and XPS foam panels.

Stay tuned for the Master Class at the end of the second video

Draw the tongue and groove panel:

- Draw a rectangle on the face of a floor joist — make it 3/4 in x 10 in as a starting point.

- Select the geometry and make a group (right click>Make group)

- Open group

- Make a tongue and a groove:

- Draw a box 1/4 in. x 3/8 in.

- Index the center point of the box to the center point of the 3/4 in. plywood without going past the edge to make the future groove

- Copy and move to the opposite end pushing it past the edge to be the tongue

- Delete the line at the base of the tongue to add the tongue geometry to the panel

- Move the tongue end out to 4 ft 0 in wide.

- Use the board stretcher to pull it 96 inches for a 4 x 8 sheet of plywood.

Add textures to the faces of the plywood (3:00):

- Use plywood texture on the top and bottom faces

- Paint bamboo on the sides to mimic lamination layers

- Right click the bamboo, >Position

- Rotate and shrink the layers to fit the plywood

- Use the eyedropper to paint the remaining three edges

To make a sheet of 1/2 in. plywood (4:35):

- Copy one face of the 3/4 in. tongue and groove (ctrl + C)

- Edit>Paste in place

- Move over to the side.

- Make a group

- Stretch the thickness to 1/2 inch

- Add bamboo texture to the edges

Use Plywood Panels for subfloor and wall sheathing (6:55)

- Lift the plywood onto the floor frame

- Rotate 90 degrees to run perpendicular to the joists

- Ctrl + Move to make a copy and add another full sheet, which can be offset one joist bay.

- Fill in the rest of the floor by copying and pasting 96 inches from edges covering the floor frame with full sheets.

- Cut the scrap off the ends with the board un-stretcher

- Make the floor frame and sheathing a group.

Make a phone booth (10:00)

- Add the walls back by turning on their layer.

- Select the plywood group and copy/move it to the top of the walls

- Move the plywood 5.5 inches higher to account for ceiling framing

- Turn on the ceiling joists layer.

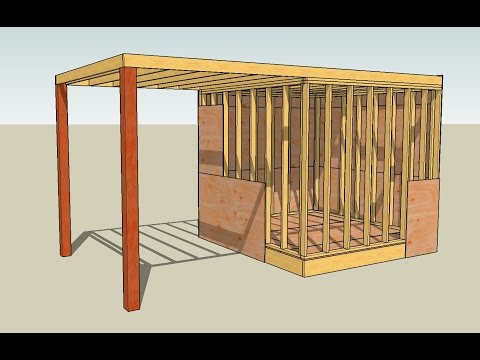

Sheathe the walls with 1/2 in plywood (11:09):

- Move the plywood to index with the bottom corner of the floor frame.

- Rotate the sheet 90 degrees to cover the wall studs.

- Copy and move additional sheets to cover the walls with full sheets

- Cut the ends off with the board un-stretcher too (P)

- Make the wall sheathing a group

- Copy and move to opposite wall

- Copy and rotate to cover the other two walls.

- Make all four walls a group and assign a new layer.

Draw Foam Board and OSB, too:

(second video in the playlist, above, Part 6 How to Draw OSB and Styrofoam Panels)

How to make the panels:

- Make a rectangle 4 ft x 8 ft.

- Make a group.

- Copy and move two times.

- Make each panel a different thickness with push/pull tool: 7/16 inch for OSB, 1 inch for Polyiso, and 2 inches for XPS.

- Color the parts. All sides of the OSB can be colored with the same texture (OSB from wood pallette) because OSB looks the same from every direction. Almost.

- Polyiso has a light yellow core and foil facing. Select all, color yellow, then color each large face with foil from the metal texture palette. The XPS is the same color throughout, Matt makes it blue.

Building with Bytes: How to Install and cut the panels (4:30)

(Similar process to installing plywood outlined above.)

Master Class: Adding text to building components (10:50)

- Open the foam panel group

- Open the text tool

- Matt uses Arial black, type in the product: Un-certi-foam

- Deselect the Form 'Filled' and 'Extruded' boxes

- When you create the text layer, it is created as a component

- While it is still selected, explode the component into its individual parts

- With the individual parts selected, make it a group

- Move the group to reveal the straggling hidden layer

- Delete the extra layer

- Explode the group to make each letter its own geometry stuck to the face of the foam

- Clean up the geometry in the lettering. In some cases, extra lines will some through from the font to the geometry process. sometimes deleting the extra lines breaks the continuity of the letter's outline, but it seems that using the pen tool to trace one segment of the letter will reconfigure the geometry. (14:40)

Cutting the panels with letters is a problem because the letters block the push pull tool. Matt selects the end geometry and uses the move tool to move the end where he wants it.

—Matt Jackson is a master carpenter, remodeler, SketchUp Wiz, YouTuber, and contributing editor to ProTradeCraft. He lives and works in Rapid City, South Dakota.